4.

After warm-up operation, check that the machine monitor

(5) is in the following conditions.

(6) Engine coolant temperature gauge

The graduation of gauge is within normal range.

(7) Fuel gauge

The graduation of gauge is within normal range.

(8) Caution lamp display

OFF

If any problem is found, perform maintenance or repair.

5.

Check for abnormal exhaust gas color, noise, or vibration.

If any abnormality is found, contact your Komatsu distributor.

6.

Set the lock lever (2) to LOCK position (L).

7.

Operate the following levers and pedals, and check that

the machine does not move.

• Work equipment operation and swing operation can-

not be done by R.H. and L.H. work equipment control

levers.

• Machine does not travel by operating R.H. and L.H.

travel levers.

• Blade does not move by operating blade control lever.

• Boom does not swing by operating boom swing con-

trol pedal.

Warm-up operation of the engine is completed.

Then, perform the warm-up operation for the hydraulic components.

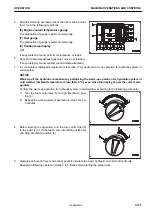

METHOD FOR HYDRAULIC SYSTEM WARM-UP OPERATION

k

k

WARNING

• Before warming up the hydraulic component, check

that there is no person or obstacle in the area around

the machine, then sound the horn and start the opera-

tion.

• The warm-up operation for the hydraulic component is

necessary not only for the circuit between the pump

and cylinders and between the pump and motor, but

also for the control circuits.

Do not perform the operation just for one cylinder or

motor, or the operation just in one direction. Perform

the operation in all directions for all the work equip-

ment (boom, arm and bucket), swing, travel, and at-

tachment (if equipped).

• Check the direction of the track frame before operating

the travel lever.

RKA63560

OPERATION

MACHINE OPERATIONS AND CONTROLS

3-125

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......