REMARK

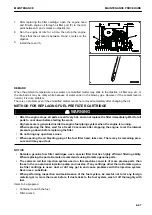

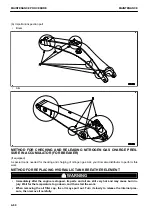

• The fresh air filter must be installed facing it in the cor-

rect direction.

• When installing, insert long end (L) of filter (5) into

duct (6) first. If short end (S) is inserted first, filter (5)

will get stuck with protrusion (B) of the sheet metal

• Keep the filter away from protrusion (B) of the sheet

metal and insert it from the top first.

If the insertion is not enough or the filter is forcibly in-

serted from bottom, it may be deformed or broken.

After inserting it, pull it to the inside of protrusion (C) of

duct (6).

5.

Close the cover and lock with the starting switch key.

Do not forget to remove the starting switch key after lock-

ing.

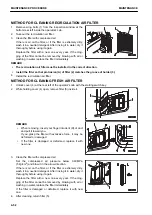

METHOD FOR CLEANING PTO LUBRICATION FILTER STRAINER

k

k

WARNING

Immediately after the engine is stopped, its parts and oil are still very hot, and may cause burn injury.

Wait for the temperature to go down, and then start the work.

1.

Remove the filter case (1).

2.

Remove the strainer, and remove any dirt stuck to the

strainer, then wash it in flushing oil.

If the strainer or O-ring is broken, replace it with a new

one.

3.

Install the strainer, and install the filter case (1).

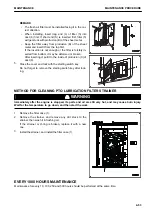

EVERY 1000 HOURS MAINTENANCE

Maintenance for every 10, 100, 250 and 500 hours should be performed at the same time.

MAINTENANCE

MAINTENANCE PROCEDURE

4-53

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......