1.

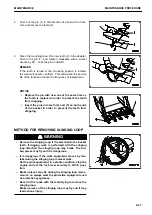

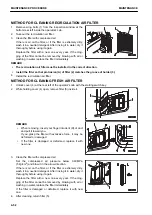

Set a container to catch the oil under the pilot line filter.

2.

Remove the plug (1).

3.

Take out the strainer (2) and wash it.

4.

Replace the O-ring (3) with a new one.

5.

Install the washed strainer (2).

• Tightening torque of the strainer: 8.64 to 9.8 Nm{0.9 to

1.0 kgm}

Fix the cylinder at 2 places.

6.

Install the O-ring (3) and the plug (1).

• Tightening torque of the plug: 107.8 to 147.0 Nm {11

to 15 kgm}

CHECKS BEFORE STARTING

For the following items, see OPERATION, “METHOD FOR CHECKING BEFORE STARTING”.

• Method for checking coolant level, adding coolant

• Method for checking oil level in engine oil pan, adding oil

• Method for checking fuel level, adding fuel

• Method for discharging water and sediment from fuel tank

• Method for checking water separator, discharging water and sediment

• Method for checking oil level in hydraulic tank, adding oil

• Method for checking oil level in swing machinery case, adding oil

• Method for checking oil level in coupling case, adding oil

• Method for checking electric wiring

• Method for checking working lamp

• Method for checking horn function

• Method for checking DEF level, adding DEF

EVERY 10 HOURS MAINTENANCE

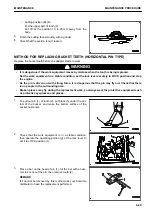

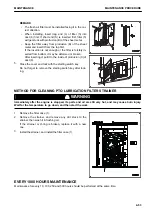

METHOD FOR LUBRICATING

1.

Set the machine to the greasing posture shown below, and lower the work equipment to the ground, then

stop the engine.

2.

By using a grease pump, pump in grease through the grease fittings shown by arrows.

• For handling the grease pump, see “GREASE PUMP”.

3.

After greasing, wipe off any old grease that is pushed out.

MAINTENANCE PROCEDURE

MAINTENANCE

4-40

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......