MAINTENANCE

MAINTENANCE PROCEDURE

4-45

BLEEDING AIR FROM HYDRAULIC SYSTEM

4

For details, see “STARTING ENGINE (3-128)“. If it is necessary to refer to the items for starting the engine,

moving the machine off, steering, or stopping, see the OPERATION section.

1.

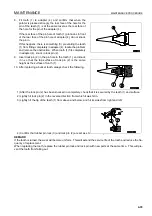

Bleeding air from pump

1) Loosen air bleeder (1) and check that oil oozes out from

the air bleeder.

2) If the oil does not ooze out, remove the drain hose from

the hydraulic pump case and fill the pump case completely

with hydraulic oil through drain port (2).

Hold the removed hose firmly, keeping the mouthpiece

higher than the oil level in the hydraulic tank so that oil will

not spill out of the hose.

3) After completing the air bleed operation, tighten air

bleeder (1) and install the drain hose.

NOTICE

If the drain hose is installed first, oil will spurt out from bleeder hole (1).

If the pump is operated without filling the pump case with hydraulic oil, abnormal heat will be generated

and this may cause an unexpected damage to the pump.

2.

Starting engine

Start the engine, referring to “STARTING ENGINE (3-128)“.

Run the engine at low idle for 10 minutes after starting, then start operations.

3.

Bleeding air from cylinders

1) Run the engine at low idle, and extend and retract each cylinder 4 to 5 times, taking care that a cylinder is not

moved to the end of its stroke. (Stop the cylinder approx. 100 mm short of its stroke end)

2) Next, operate each cylinder 3 to 4 times to the end of its stroke.

3) Finally, operate each cylinder 4 to 5 times to the end of its stroke to completely remove the air.

NOTICE

If the engine is run at high speed immediately after startup or a cylinder is pushed up to its stroke end, air

taken inside the cylinder may cause damage to the piston packing.

4.

Bleeding air from swing motor

1) Run the engine at low idling, loosen hose (3) at port S,

and check that oil oozes out from port S hose (3).

NOTICE

Do not operate the swing under any circumstances.

2) If oil does not ooze out, stop the engine, remove port S

hose (3), and fill the inside of the motor case with hydraulic

oil.

3) After completely bleeding the air from the swing motor, tighten port S hose (3).

4) Run the engine at low idle and slowly swing at least two times uniformly to the left and right. This will automat-

ically bleed the air from the swing circuit.

Summary of Contents for PC450-8

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 66: ...SAFETY MAINTENANCE INFORMATION SAFETY 2 42 ...

Page 351: ...SPECIFICATIONS 15 ...

Page 355: ...SPECIFICATIONS SPECIFICATIONS 5 5 6 7m Boom PC450 8 ...

Page 356: ...SPECIFICATIONS SPECIFICATIONS 5 6 6 7m Boom PC450LC 8 ...

Page 357: ...SPECIFICATIONS SPECIFICATIONS 5 7 6 7m Boom PC450LCHD 8 ...

Page 359: ...SPECIFICATIONS SPECIFICATIONS 5 9 7 0m Boom PC450 8 ...

Page 360: ...SPECIFICATIONS SPECIFICATIONS 5 10 7 0m Boom PC450LC 8 ...

Page 410: ...SUPER LONG FRONT BOOM AND ARM ATTACHMENTS ANDD OPTIONS 6 50 ...

Page 436: ...OPERATION HIGH REACH DEMOLITION EQUIPMENT 27M 7 26 3 Extend arm cylinder Arm cylinder ...

Page 469: ...INDEX 18 ...

Page 470: ...INDEX 8 2 ...

Page 473: ...COLOPHON 18 ...