MAINTENANCE PROCEDURE

MAINTENANCE

4-36

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)

4

Replace the bucket teeth before the adapter starts to wear.

WARNING

q

It is dangerous if the work equipment moves by mistake when the teeth are being replaced.

Set the work equipment in a stable condition, then stop the engine and set the lock lever securely to

the LOCK position.

q

The pins can be knocked out only with strong force, so there is a hazard that the pin may fly out.

Check that there is no one in the surrounding area.

q

There is a hazard that fragments will fly during the replacement work, so always wear protective equip-

ment like safety glasses and gloves.

1.

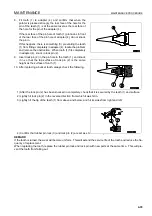

To make it possible to knock out pin (1) of tooth (2), put

block (5) under the bottom of the bucket, and set so that

the bottom surface of the bucket is horizontal.

2.

Check that the work equipment is in a stable condition,

then set the lock lever to the LOCK position (L).

3.

Place a bar on the head of pin (1), hit the bar with a ham-

mer to knock out the pin, then remove tooth (2).

REMARK

If the bucket teeth cannot be safely removed by this method,

have your Komatsu distributor replace the bucket teeth.

Summary of Contents for PC450-8

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 66: ...SAFETY MAINTENANCE INFORMATION SAFETY 2 42 ...

Page 351: ...SPECIFICATIONS 15 ...

Page 355: ...SPECIFICATIONS SPECIFICATIONS 5 5 6 7m Boom PC450 8 ...

Page 356: ...SPECIFICATIONS SPECIFICATIONS 5 6 6 7m Boom PC450LC 8 ...

Page 357: ...SPECIFICATIONS SPECIFICATIONS 5 7 6 7m Boom PC450LCHD 8 ...

Page 359: ...SPECIFICATIONS SPECIFICATIONS 5 9 7 0m Boom PC450 8 ...

Page 360: ...SPECIFICATIONS SPECIFICATIONS 5 10 7 0m Boom PC450LC 8 ...

Page 410: ...SUPER LONG FRONT BOOM AND ARM ATTACHMENTS ANDD OPTIONS 6 50 ...

Page 436: ...OPERATION HIGH REACH DEMOLITION EQUIPMENT 27M 7 26 3 Extend arm cylinder Arm cylinder ...

Page 469: ...INDEX 18 ...

Page 470: ...INDEX 8 2 ...

Page 473: ...COLOPHON 18 ...