MACHINE OPERATIONS AND CONTROLS

OPERATION

3-166

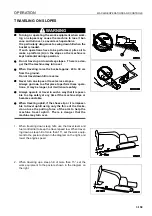

3.

After removing the bucket, reverse it.

4.

Align arm (5) with replacement bucket hole (1), then align

link (6) with hole (2), coat pins (A) and (B) with grease, and

install.

REMARK

When reversing, do not install an O-ring. Keep the O-ring in a

safe place until using it next.

5.

Install the stopper bolts and nuts for each pin, then grease

the pin.

REMARK

Lubricate with grease thoroughly until the grease comes out

from the end face.

When replacing the bucket, replace the dust seal if it has been

damaged. If a damaged seal is used without being replaced,

sand and dirt may enter the pin portion and cause abnormal

wear of the pin.

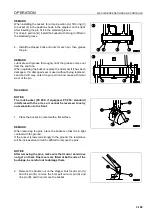

PARKING MACHINE

3

WARNING

q

Avoid stopping suddenly. Give yourself ample room

when stopping.

q

When stopping the machine, select flat hard ground

and avoid dangerous places.

If it is unavoidably necessary to park the machine on a

slope, insert blocks underneath the track shoes. As an

additional safety measure, thrust the bucket into the

ground.

q

If the control lever is touched by accident, the machine

may move suddenly, and this may lead to a serious

accident.

Before leaving the operator's compartment, always set

the lock lever securely to LOCK position.

Summary of Contents for PC450-8

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 66: ...SAFETY MAINTENANCE INFORMATION SAFETY 2 42 ...

Page 351: ...SPECIFICATIONS 15 ...

Page 355: ...SPECIFICATIONS SPECIFICATIONS 5 5 6 7m Boom PC450 8 ...

Page 356: ...SPECIFICATIONS SPECIFICATIONS 5 6 6 7m Boom PC450LC 8 ...

Page 357: ...SPECIFICATIONS SPECIFICATIONS 5 7 6 7m Boom PC450LCHD 8 ...

Page 359: ...SPECIFICATIONS SPECIFICATIONS 5 9 7 0m Boom PC450 8 ...

Page 360: ...SPECIFICATIONS SPECIFICATIONS 5 10 7 0m Boom PC450LC 8 ...

Page 410: ...SUPER LONG FRONT BOOM AND ARM ATTACHMENTS ANDD OPTIONS 6 50 ...

Page 436: ...OPERATION HIGH REACH DEMOLITION EQUIPMENT 27M 7 26 3 Extend arm cylinder Arm cylinder ...

Page 469: ...INDEX 18 ...

Page 470: ...INDEX 8 2 ...

Page 473: ...COLOPHON 18 ...