For details, see“METHOD FOR INSTALLING HYDRAULIC TANK OIL FILLER CAP (3-148)”.

METHOD FOR CHECKING AND RELEASING NITROGEN GAS CHARGE PRES-

SURE IN ACCUMULATOR (FOR CONTROL CIRCUIT)

k

k

WARNING

The accumulator is charged with high-pressure nitrogen gas, so improper operation may cause an ex-

plosion, which will lead to serious injury or death. For handling, always observe the following.

• The pressure in the hydraulic circuit cannot be completely removed. When removing the hydraulic

equipment, do not stand in the direction that the oil spurts out when performing the operation. In

addition, loosen the bolts slowly when performing the work.

• Do not disassemble it.

• Do not bring open flame close to it or do not dispose of it in fire.

• Do not perform drilling, welding or flame-cutting.

• Do not hit or roll it, or subject it to any impact.

• When disposing of it, the gas must be released. Ask your Komatsu distributor to have this work per-

formed.

NOTICE

If the nitrogen gas charge pressure in the accumulator is low and operations are continued, it becomes

impossible to release the remaining pressure inside the hydraulic circuit if a failure occurs on the ma-

chine.

FUNCTION OF ACCUMULATOR

The accumulator has function of storing pressure of the control circuit in it. Even if the engine is stopped, the

control circuit can be operated as long as the accumulator functions normally, so the following actions are possi-

ble.

• When the control lever is operated in the direction to lower the equipment, the work equipment goes under

its own weight.

• Release the pressure from the hydraulic circuit.

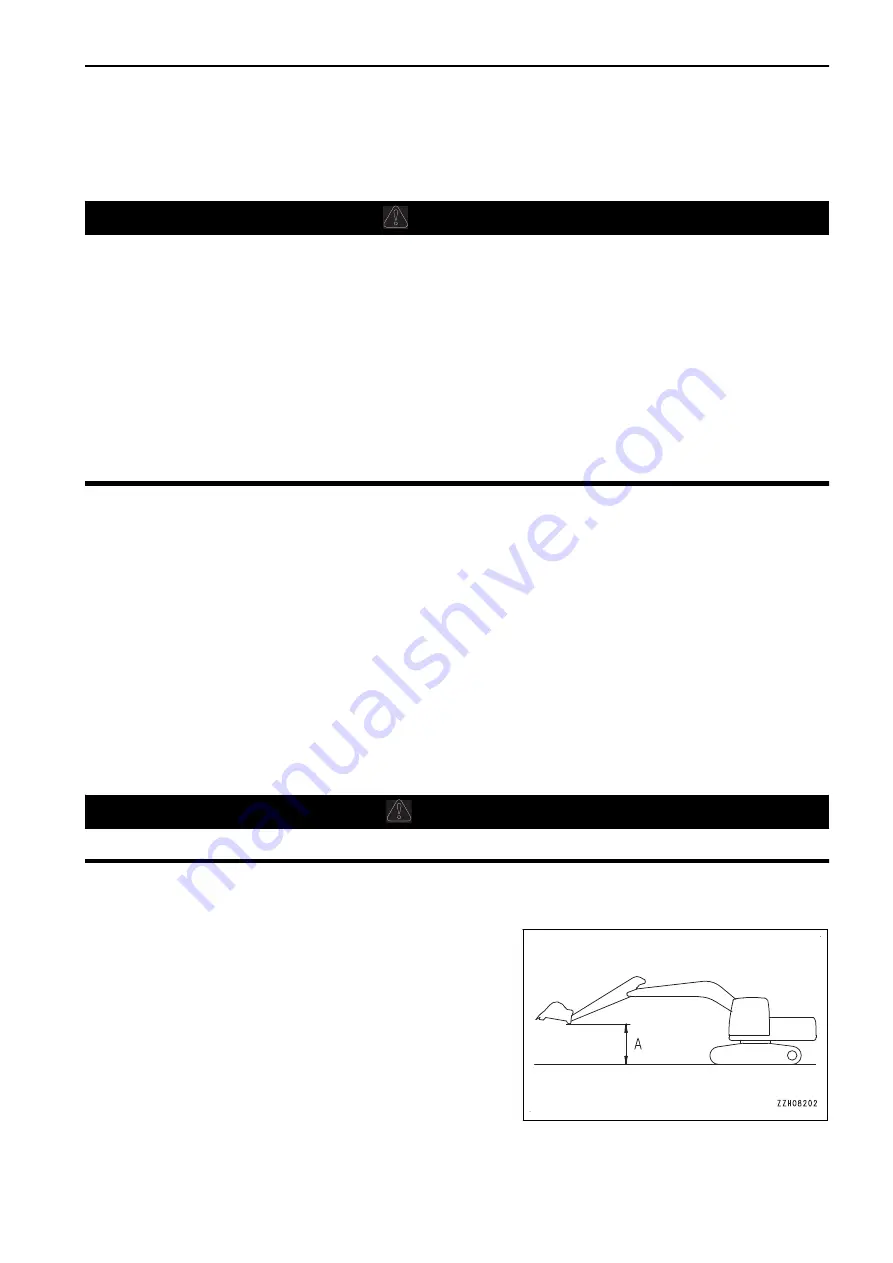

The accumulator is installed to the position shown in the figure.

METHOD FOR CHECKING ACCUMULATOR FUNCTION

k

k

CAUTION

When performing the inspection, check first that there is no person or obstacle in the surrounding area.

Check the nitrogen gas charge pressure as follows.

1.

Place the machine on a flat ground.

2.

Hold the work equipment in the maximum reach posture

(arm fully OUT, bucket fully DUMP) at height (A) 1.5 m

from the ground.

3.

Perform the following procedure within 15 seconds.

MAINTENANCE

MAINTENANCE PROCEDURE

4-67

Summary of Contents for PC360LC-11

Page 2: ......

Page 22: ......

Page 76: ......

Page 344: ......

Page 425: ...SPECIFICATIONS 5 1 ...

Page 429: ...PC360NLC 11 SPECIFICATIONS SPECIFICATIONS 5 5 ...

Page 430: ......

Page 450: ...PC360LC 11 2 Piece Boom PC360NLC 11 2 Piece Boom 2 PIECE BOOM ATTACHMENTS AND OPTIONS 6 20 ...

Page 457: ...ATTACHMENTS AND OPTIONS 17M LONG REACH BOOM AND ARM 6 27 ...

Page 465: ...ATTACHMENTS AND OPTIONS SUPER LONG FRONT BOOM AND ARM 6 35 ...

Page 499: ...REPLACEMENT PARTS 7 1 ...

Page 515: ......