2.

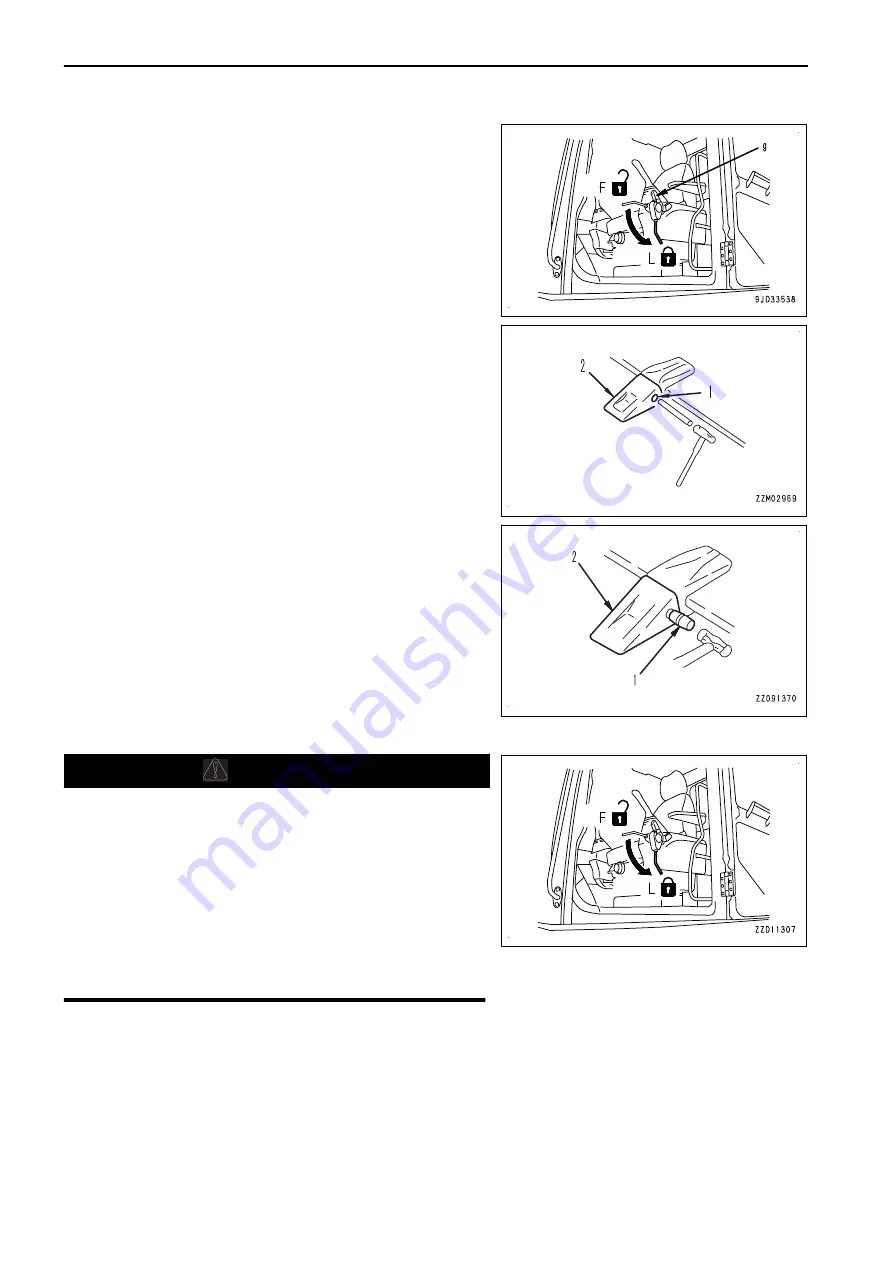

Check that the work equipment is in a stable condition,

then operate the control grip (g) of the lock lever to set it to

LOCK position (L).

3.

Place a bar on the head of pin (1), hit the bar with a ham-

mer to knock out the pin, then remove tooth (2).

REMARK

If it cannot be removed by this method, ask your Komatsu

distributor to have the replacement performed.

4.

Clean the mounting face. Fit a new tooth (2) in the adapter,

push in pin (1) partially by hand, then lock it with a hammer

to install the tooth to the bucket.

METHOD FOR REPLACING BUCKET SIDE CUTTER AND SHROUD

k

k

WARNING

It is dangerous if the work equipment moves by mistake

when replacing the side cutter and shroud of the bucket.

Set the work equipment in a stable condition, and stop the

engine. Then set the lock lever securely to LOCK position

(L).

As the pin is driven out with strong force, it is dangerous

that the pin may fly out. Check that there are no people in

the surrounding area.

Broken pieces may fly during the replacement work, so al-

ways wear the protective equipment such as protective

eyeglasses and gloves.

MAINTENANCE PROCEDURE

MAINTENANCE

4-30

Summary of Contents for PC360LC-11

Page 2: ......

Page 22: ......

Page 76: ......

Page 344: ......

Page 425: ...SPECIFICATIONS 5 1 ...

Page 429: ...PC360NLC 11 SPECIFICATIONS SPECIFICATIONS 5 5 ...

Page 430: ......

Page 450: ...PC360LC 11 2 Piece Boom PC360NLC 11 2 Piece Boom 2 PIECE BOOM ATTACHMENTS AND OPTIONS 6 20 ...

Page 457: ...ATTACHMENTS AND OPTIONS 17M LONG REACH BOOM AND ARM 6 27 ...

Page 465: ...ATTACHMENTS AND OPTIONS SUPER LONG FRONT BOOM AND ARM 6 35 ...

Page 499: ...REPLACEMENT PARTS 7 1 ...

Page 515: ......