MAINTENANCE PLAN

143

4.7.1.d

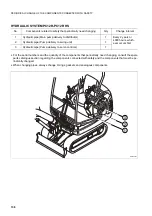

CHECKING THE STEEL TRACK TENSION

CHECK

ADJUSTMENT

DANGER

•

This operation must be carried out by two operators. One operator must be seated in the cab and oper-

ate the machine according to the instructions of the operator who carries out the check and the adjust-

ment.

•

The track tension must be checked with the frame lifted from the ground; be careful not to move any

control lever while the operator is carrying out the check.

Stop the machine on a firm and level surface, after lowering the

equipment to the ground.

1 - Raise each track by means of boom and arm.

Operate the control levers slowly during this operation.

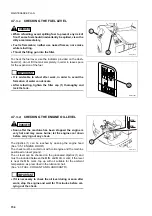

2 - Measure the distance between the track and the second roll-

er, starting from the sprocket. If the distance is included be-

tween 10 and 20 mm, the tension is normal.

If the value is not included in this interval, adjust the track un-

til reaching the correct value.

RWA06380

10÷20 mm

RWA06530

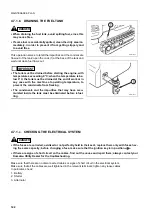

DANGER

•

The grease contained in the hydraulic cylinder is under

pressure. For this reason, do not loosen the greasing

valve (3) giving it more than one turn; if the valve is loos-

ened excessively, it may be pushed out due to the grease

pressure and this is very dangerous for the operator.

Do not loosen any other component in addition to the

valve (3).

•

If you notice excessive resistance while injecting grease,

slowly move the machine forward and backward for a

short distance.

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...