PERIODICAL CHANGE OF SAFETY-RELATED COMPONENTS

184

WEAM009500

4.7 PERIODICAL CHANGE OF SAFETY-RELATED COMPONENTS

To ensure safety at any moment while driving and using the machine, the operator must carry out all the routine

maintenance operations prescribed. Furthermore, the operator must periodically change the components indicat-

ed in the table in the following page, which are especially related to safety and fire-prevention rules. These compo-

nents are subject to wear and since it is particularly difficult to evaluate their conditions through simple routine

maintenance, after a certain time interval it is advisable to change them independently of their state, in order to

keep them efficient over time. Repair or replace these components immediately in case of failures or anomalies,

even if the time interval prescribed for their change has not elapsed yet.

If the pipe clamps show signs of deterioration, like deformations or cracks, provide for changing them together with

the pipes.

In addition to the periodical change of the components listed in the following page, the inspections described be-

low are to be carried out on the hydraulic pipes. Whenever anomalies are detected, carry out the necessary ad-

justment operations and replacements, or take any other measure required.

For the quantities and codes of the safety-related components to be changed, see the spare parts catalogue.

When changing pipes, always change O rings, gaskets and analogous components.

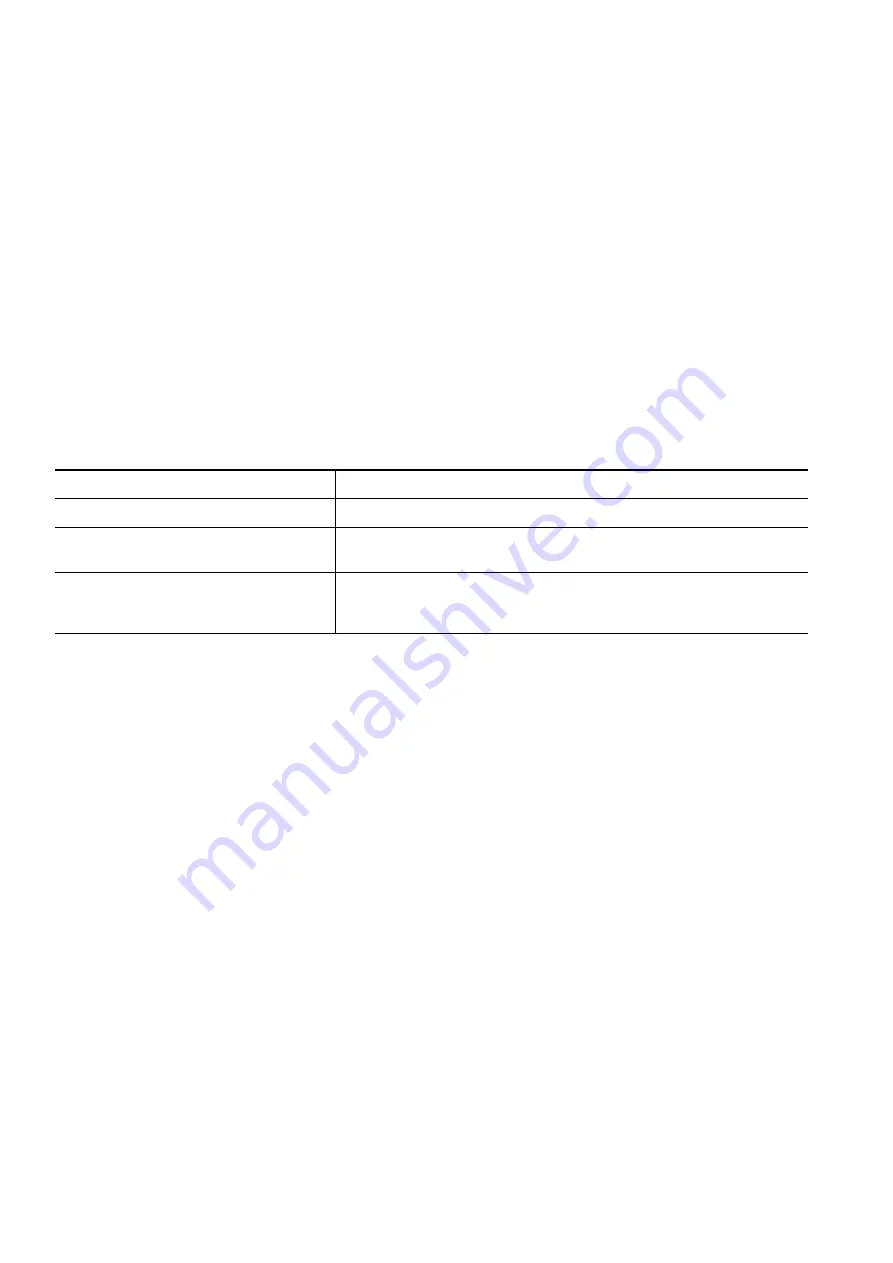

Type of check

Items to be checked

Before starting the engine

Leakages from joints, hydraulic pipes or fuel pipes.

Periodically (monthly)

Leakages from joints, hydraulic pipes or fuel pipes. Damaged hydraulic or fuel

pipes (cracks, wear and tear).

Periodically (yearly)

Leakages from joints, hydraulic pipes or fuel pipes. Deteriorated, twisted,

damaged hydraulic or fuel pipes (cracks, wear and tear) or pipes in contact

with other parts of the machine.

Summary of Contents for PC26MR-3

Page 2: ......

Page 19: ...SAFETY AND ACCIDENT PREVENTION 17 ...

Page 62: ...60 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 63: ...THE MACHINE AND ITS OPERATIONS 61 ...

Page 170: ...168 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 171: ...MAINTENANCE 169 ...

Page 226: ...224 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 227: ...TECHNICAL SPECIFICATIONS 225 ...

Page 234: ...232 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 235: ...AUTHORISED EQUIPMENT 233 ...

Page 250: ...248 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 251: ......

Page 252: ... 2008 KOMATSU UTILITY EUROPE S p A All Rights Reserved Printed in Europe 01 2008 ...