8.9 Motor Power, Brake and Feedback connection

The AKD2G drive is able to protect the connected motor from overloading, if the parameters

are set correctly and the thermal protection sensor is connected and supervised. With Koll-

morgen motors the valid data are automatically set by the WorkBench motor database. Refer

to parameter AXIS#.MOTOR.RTYPE for supported thermal sensors.

The dynamic voltage rise can lead to a reduction in the motor operating life and, on unsuit-

able motors, to flashovers in the motor winding.

Only install motors with insulation class F (acc. to IEC60085) or above.

Only install cables that meet the requirements (

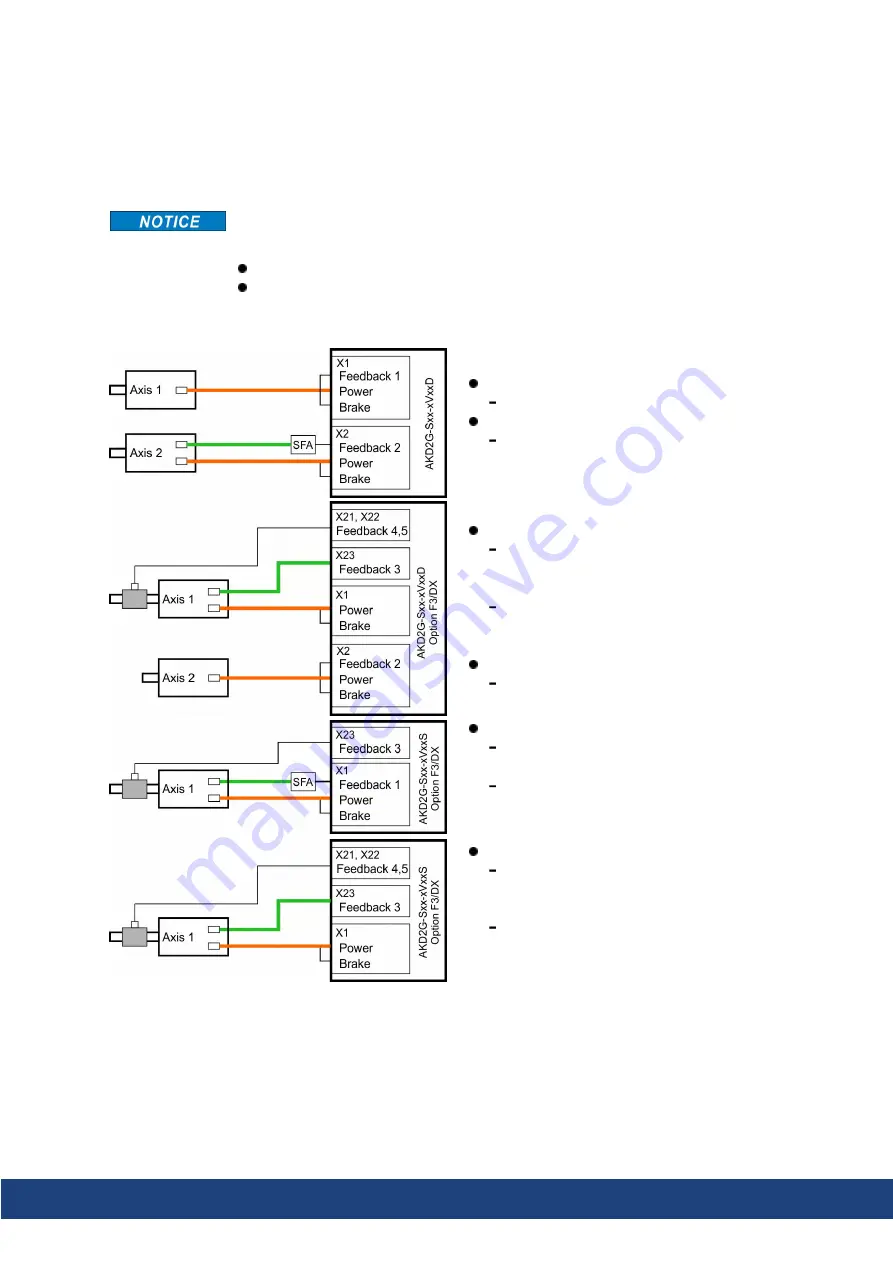

8.9.1 Motor connectivity, some examples

Axis 1: single cable connection (

commutation feedback: SFD3 or DSL

Axis 2: dual cable connection (

commutation feedback: EnDAT, HIPERFACE,

Resolver etc. by using SFA

Axis 1: dual cable connection (

commutation feedback: Resolver, SFD, EnDAT,

HIPERFACE, BiSS, SinCos, ComCoder, Hall,

SmartAbs etc. by using X23

position feedback:

- X21: Step/Direction

- X22: Step/Direction or incremental encoder

Axis 2: single cable connection (

commutation feedback: SFD3 or DSL

Axis 1: dual cable connection (

commutation feedback: EnDAT, HIPERFACE,

Resolver etc. by using SFA

position feedback:Resolver, SFD, EnDAT,

HIPERFACE, BiSS, SinCos, ComCoder, Hall,

SmartAbs etc. by using X23

Axis 1: dual cable connection (

commutation feedback: Resolver, SFD, EnDAT,

HIPERFACE, BiSS, SinCos, ComCoder, Hall,

SmartAbs etc. by using X23

position feedback:

- X21: Step/Direction

- X22: Step/Direction or incremental encoder

AKD2G-S Installation Manual, Safety 1 | 8 Electrical Installation

Kollmorgen | kdn.kollmorgen.com | July 2020

79