Installation and connection

Diaphragm pump N630.12

32

Translation of Original Operating and Installation Instruction, english, KNF 318761-318764 02/22

Connecting the pump

CAUTION

Risk of injury from mixing up suction side and

pressure side

Mixing up the suction side and pressure side can

result in breakage of connected components on

the suction side and pressure side.

à

Observe the marking of inlet and outlet on

the pump head.

1. Remove the protective plugs from the hose connection threads.

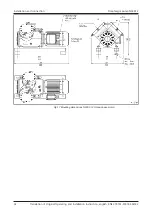

2. Connect the suction line and the pressure line (for mounting dimen-

).

3. Lay the suction line and pressure line with a descent so that no con-

densate can run into the pump.

Pneumatic noises can be reduced or dissipated by using a silencer

(see Chapter

).

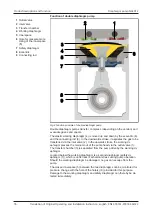

6.4 Installing monitoring device and monitoring

diaphragm innerspace

Fig.15 Sectional drawing of hole for

pressure monitoring

WARNING

Risk of dangerous gas mixtures during pump op-

eration if the working diaphragm breaks

Depending on the medium being transferred,

breakage of the working diaphragm can result in a

dangerous mixture if the medium mixes with the

air in the innerspace between the working di-

aphragm and the safety diaphragm.

à

KNF recommends monitoring the innerspace

between the working diaphragm and the

safety diaphragm (see Fig. 4) through the

hole(s) (see Fig. 15) in the intermediate ring

for a change in pressure or the presence of

gas. If the pressure changes in the in-

nerspace, the pump is to be stopped immedi-

ately.

à

Immediately stop the pump if the working di-

aphragm breaks. Replace the working di-

aphragm and safety diaphragm prior to further

operation (see Chapter

Summary of Contents for N630.12

Page 65: ...13...

Page 67: ...15 9 Documents provided Circuit diagram...

Page 69: ......

Page 82: ...13...

Page 84: ...15 9 Documents provided Circuit diagram...

Page 87: ......

Page 88: ...KNF worldwide You can find our local KNF partners at www knf com...