6 FAULT

DIAGNOSTICS

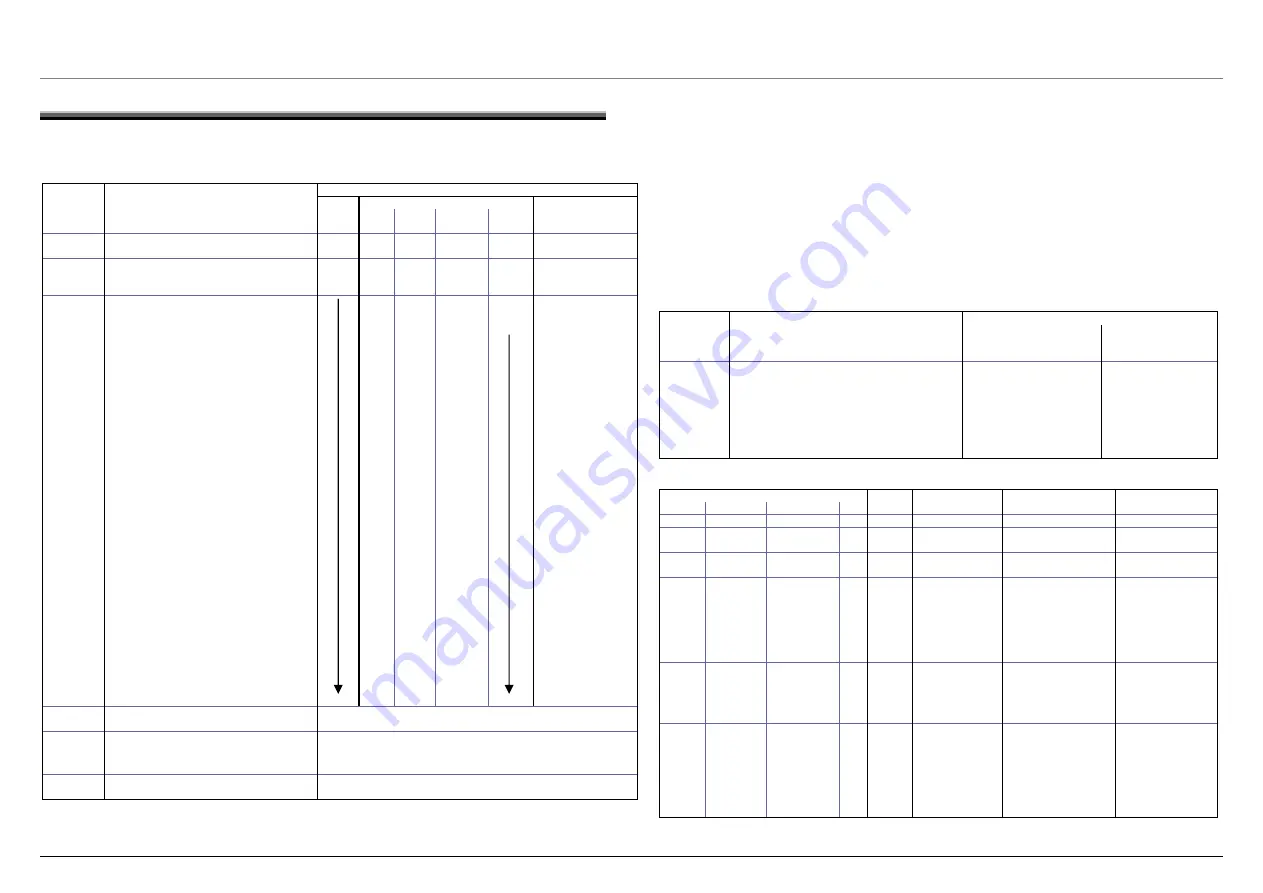

2. S

c

Obs

c

Display

ele ting the test program

erve orrect method for setting program selector!

LEDs(Indicator)

y Cupboard

dry

End

Display

Button

LED Drying Iron

dr

Activ

e

men

ate t st Program selector switch to OFF position

Off

u:

One time last error

Turn the appliance on by pressing the Start

and Delicates button simultaneously and

Start is

flashing

turning the selector switch (either direction). quick

Activ

e

is

flashing

quick

ate t st In test menu set program selector switch to

program:

a test program:

Read out error storage

1st position to the right

2nd position to the right

Test program for safety test

3rd position to the right

Display test (LED/LCD)

4th position to the right

Control elements test

5th position to the right

Consumer test

6th position to the right

Laundry resistance measurement test

7th position to the right

Demo program

8th position to the right

Changeover 10A/16A (208V/240V)

operation

1st position to the left

Automatic end-of-line program

Start test

program:

Press START button

LED Start is illuminating

Abort test

program:

Adjust program selector switch or press

START button

LED Start is flashing

Switch off appliance

Leave test

program:

Switch off appliance

t on one side with the phase ) switch on. The test must be done using

For this propose the following Inspection Process is adaptive

Connect app

ine

tton Extra dry

4.

The current consumption on tester (Motor and Heater Elements must be switch on)

1. Safety test

For the safety test must Heater Element (at leas

different current method.

1.

liance with tester and power l

2.

Choose program with Heater; example Co

3. Program

start

The Maximal Different Current must be under allowable limit while checking procedures is running.

Annotation:

Depending on used tester (for example Meratester 5-f) can be necessary inspection process with 180° twisted power

connector ones again do.

Inspection Process must be done with cold Appliance to prevent that Heater Element is switch on.

2.1 Fault display

Display

Test: Sequence:

Standard Indicator

Display

E: failure number

C: numbers of failure

Last fault

- the last fault is displayed at first

Start and finished LED’s are E:XX is displayed

flashing

Fault history - after further operation the START button, the

content of the error register (of the last 8 cycles)

is indicated

LED Start is illuminating

Status-LED’s: failure code

E:XX is displayed

C:XX is displayed

Or blank if no failure

Last fault

- if all register were indicated, the first fault is

Filter- outflow hose LEDs

E:XX is displayed

displayed again by operation the START button are flashing

C:XX is displayed

Or blank if no failure

LEDs (Indicator)

Drying

Iron dry

Cupboard dry End

description

cause

Display

Fault / fault

Remarks, possible

Results

No

fault

is

flashing

E:11

Fluffing level 1

- Fluff filter, container

or air routes blocked

- Clean components

and air routes

is flashing

E:12

Fluffing level 2

- Fluff filter, container

or air routes blocked

- Clean components

and air routes

is

flashing

is flashing

E:13

Maximum drying

time exceeded

- Heater or heater

control damaged

- Bimetal switch was

triggered

- Laundry load (to

heavy or to wet)

- Check heating

circuit and bimetal

switch, replace

damaged parts

- Reduce laundry

load or select

adequate program

is

fl

ashing

is flashing

E:15

Fault in heating

circuit

- Excess temperature

of the heater is

detected

- Check air routes,

heater function and

heater control;

replace damaged

parts

is

fl

ashing

is flashing is flashing

E:17

Door-NTC fault

(TD)

- Damaged sensor

- Short circuit in sensor

wire

- Open sensor circuit

- Control interpretation

fault

- Check wires and

connectors, replace

damaged parts

- Short circuits and

breaks are detected

by control after

switch-on

702_58300000121945_ara_en_a

Page 17 of 21