IMPORTANT NOTICE:

DO NOT return to place of purchase!!!

Please contact Customer Service hotline at 800-913-8999 for help.

SAFETY CHECKS

STEP 1:

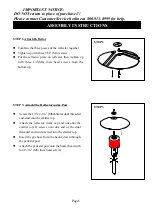

1.

Check connection of the regulator to the propane tank

3

1

2

STEP 1.

connection. Remember, the POL adapter is a left-hand

thread. (See diagram for Step 1)

2.

Check all connections on the hose regulator assembly

(See diagram for Step 1)

3.

Check the intake hose to make certain that

it is not kinked or in a position that could cause it to

kink. Hand tighted and then make a 1/2 turn with the

adjustable wrench. (See diagram for Step 1)

NOTE: The remaining connections are to be tested after

the heater has been lit.

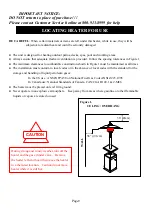

STEP 2:

4.

Light the heater following instructions on page 10

and page 11.

6

8

7

9

STEP 2.

5.

Using spray bottle with soapy water, spray each of

the areas listed below to visually inspect for leaks.

leaks will be indicated by bubbles.

6.

Intake hose fitting at the bottom of safety control

valve. (See diagram for Step 2)

7.

Pilot tubing to safety control valve. (See diagram for Step 2)

8.

Orifice fitting and the safety control valve. (See diagram for

Step 2)

9.

Pilot tubing and pilot. (See diagram for Step 2)

NOTE:

After leak testing is completed and all leaks

are sealed, close the door to the tank enclosure and

your patio heater is ready to use.

Page 8