FP 25 E

Operation

Issue: 06/2011

55

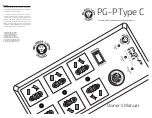

5 .2 .1 .2 General Threading through the Projector Head

• Put the full reel on the rear reel

shaft and thread the film via the rear

lever arm and extension arm.

• Run the film via the guide roller

“Projection”.

• Open the sprocket pad shoe.

- Thread the film in the feed

sprocket

(all perforations engaged in

sprocket teeth).

- Close the pad shoe.

• Thread the film in the film gate.

- Close the film pressure skate.

- One whole frame must be

centred vertically in front of

the aperture opening.

There is a small light inside the

aperture to assist in centring.

- Assure the film is centred

horizontally between the

ceramic discs.

A film loop of about 4 frames - 16

perforations (35 mm film) must be

left both just above and just below

the gate! If the loops are too big

the film will touch stationary parts

and be scratched . If the loops are

too small the film may break, the

image may jump, or the sound may

warble .

• Thread the film through guide rollers to the sound head and then to the bottom

sprocket. The sound pressure roller may be lifted to ease threading

• Open the sprocket pad shoe.

- Thread the film in the holdback/bottom sprocket (all perforations engaged in the

sprocket teeth).

- Close the pad shoe.

- Verify the loop below the gate is still OK.

• Run the film via the fore side extension arm and the lever arm.

• Wind-up the film several times around the fore side take-up spool.

“Projection”

Feed sprocket

Bottom sprocket

to take-up friction

Film

Gate

Intermittent

sprocket

Summary of Contents for FP 25 E PREMIERE

Page 2: ......

Page 22: ...FP 25 E Issue 06 2011 10 ...

Page 56: ...FP 25 E Issue 06 2011 44 ...

Page 64: ...FP 25 E Issue 06 2011 52 ...

Page 104: ...FP 25 E Issue 06 2011 92 Figure 1 1A 1C 1B 1D Figure 2 2A Fig 2A Fig 2B Fig 2C 2D 2B ...

Page 110: ...FP 25 E Issue 06 2011 98 10A Figure 11 Figure 11 11A 11B 11C Fig 11A Fig 11C Fig 11B ...