INSTALLATION INSTRUCTIONS

R−410A, Two−Stage Split System Air Conditioner

8

421 01 6002 01

I. OPENING SERVICE VALVES

Outdoor units are shipped with a refrigerant charge

sealed in the unit. Opening the service valves releases

this charge into the system.

NOTE: Open the Suction service valve first. If the Liquid

service valve is opened first, oil from the compressor may

be drawn into the indoor coil TXV, restricting refrigerant

flow and affecting operation of the system.

Remove Suction service valve cap and insert a hex

wrench into the valve stem. Hold the valve body steady

with an end−wrench and back out the stem by turning the

hex wrench counterclockwise. Turn the stem until it just

contacts the rolled lip of the valve body.

After the refrigerant charge has bled into the system,

open the Liquid service valve.

NOTE: These are not back−seating valves. It is not

necessary to force the stem tightly against the rolled lip.

The service valve cap is a primary seal for the valve and

must be properly tightened to prevent leaks. Make sure

cap is clean and apply refrigerant oil to threads and

sealing surface on inside of cap.

Tighten cap finger tight and then tighten additional

of a

turn (1 wrench flat) to properly seat the sealing surfaces.

J. GAUGE PORTS

Check for leaks at the schrader ports and tighten valve

cores if necessary. Install plastic caps finger tight.

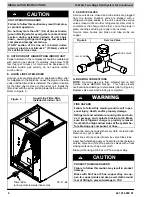

ELECTRICAL WIRING

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in per-

sonal injury or death.

Before installing, modifying or servicing system,

turn OFF the main (remote) electrical disconnect

device. There may be more than one disconnect

device.

The supply voltage must be 208/230 volts (197 volt

minimum to 253 volts maximum) 60 Hz single phase.

Outdoor units are approved for use with copper

conductors only. Do not use aluminum wire.

Refer to unit rating plate for minimum circuit ampacity and

circuit protection requirements.

Grounding

Permanently ground unit in accordance with the National

Electrical Code and local codes or ordinances. Use a

copper conductor of the correct size from the grounding

lug in control box to a grounded connection in the service

panel or a properly driven and electrically grounded

ground rod.

Wiring Connections

Make all outdoor electrical supply (Line Voltage)

connections with raintight conduit and fittings. Most

codes require a disconnect switch outdoors within sight of

the unit. Consult local codes for special requirements.

Route electrical supply (Line Voltage) wiring through

knockout hole in bottom of Control Box. Connect wires to

Contactor and Ground Lug according to Wiring Diagram

on unit. Also refer to Figure 9.

Route thermostat wiring through rubber grommet in

bottom of Control Box. Low voltage lead wires are

provided in the control box for connection to thermostat

wires (use wire nuts). Refer to Wiring Diagram on unit and

Figure 10 for low voltage wiring examples.

NOTE: Use No. 18 AWG (American Wire Gage)

color−coded, insulated (35

°

C minimum) wire. If thermostat

is located more than 100 feet (30.5m) from unit as

measured along the control voltage wires, use No. 16 AWG

color−coded wires to avoid excessive voltage drop.

Figure 9

Electrical Supply (Line Voltage)

Connections

DISCONNECT

PER NEC AND/OR

LOCAL CODES

CONTACTOR

GROUND

LUG

FIELD GROUND

WIRING

FIELD POWER

WIRING

11

23

L1

L2

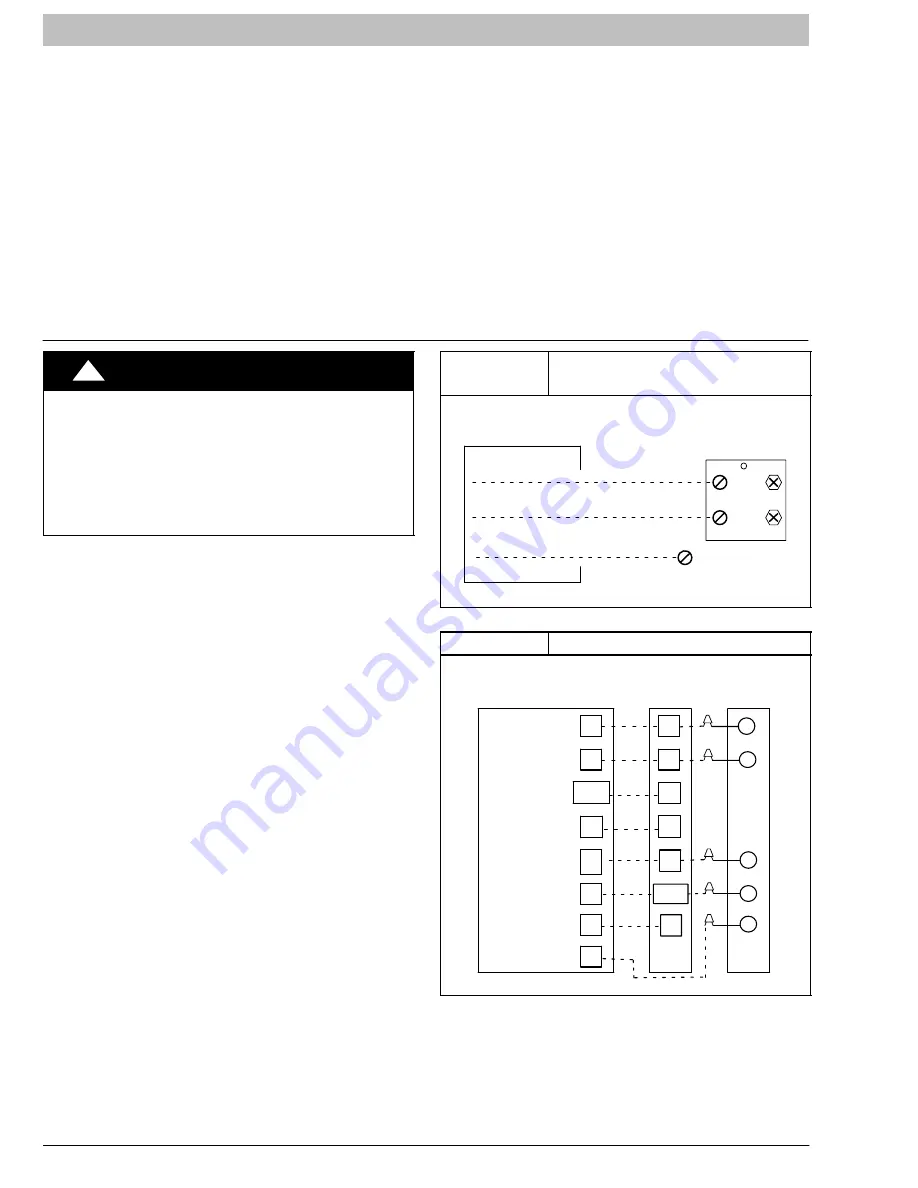

Figure 10

Typical Thermostat Connections

24 VAC HOT

24 VAC COM

R

C

W/W1

R

C

C

THERMOSTAT

HEAT STAGE 1

INDOOR FAN

TWO−STAGE

AIR CONDITIONER

R

Y2

W1

W2

Y1

Y1

W2

Y/Y2

G

G

L

Y

Y2

L

HEAT STAGE 2

LED INDICATOR

LIGHT

COOL STAGE 2

COOL STAGE 1

VARIABLE SPEED

FURNACE /

FAN COIL