There are two scales that require setting dependant upon the size of the oval/circle:

1.

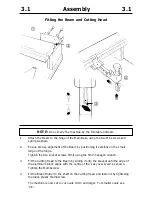

The width of the oval (or diameter of the circle) is set on the beam scale by

squeezing the release lever and cutter head support then sliding the cutter until

the red line in the window indicates the required dimension. The scale can be

read in inches or centimetres.

Scale

If the measuring scale itself slides too easily set the cutting head to

tightening

10 (cms. or ins.), slide the scale from its groove by about 10cm [4”]

and twist it to lightly distort the strip. Replace the scale and check

the friction, slide the scale to again read 10.

2.

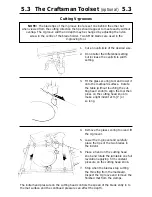

The difference between the width and length of the oval is set on the differential

scale, turn the knob counter-clockwise by half a turn to release and set to the

required dimension, lock in position. For a circle set the pointer as far to the right

as it will go (not necessarily the ‘zero’ on the scale). The scale will be set to either

inches or centimetres and can be changed by turning the scale over as follows:

3.

Set the scale to zero and remove the two screws then remove the knob and

pointer. Turn the scale over and carefully refit the pointer ensuring the small pin is

located in the hole (as shown), refit the knob and loosely refit the two screws.

Adjust the scale so that it reads zero then moderately tighten the two screws.

If you find the machine does not cut accurately the scales require calibrating – refer to

the next section.

4.1

Operation

4.1

Setting the size of the Oval/Circle