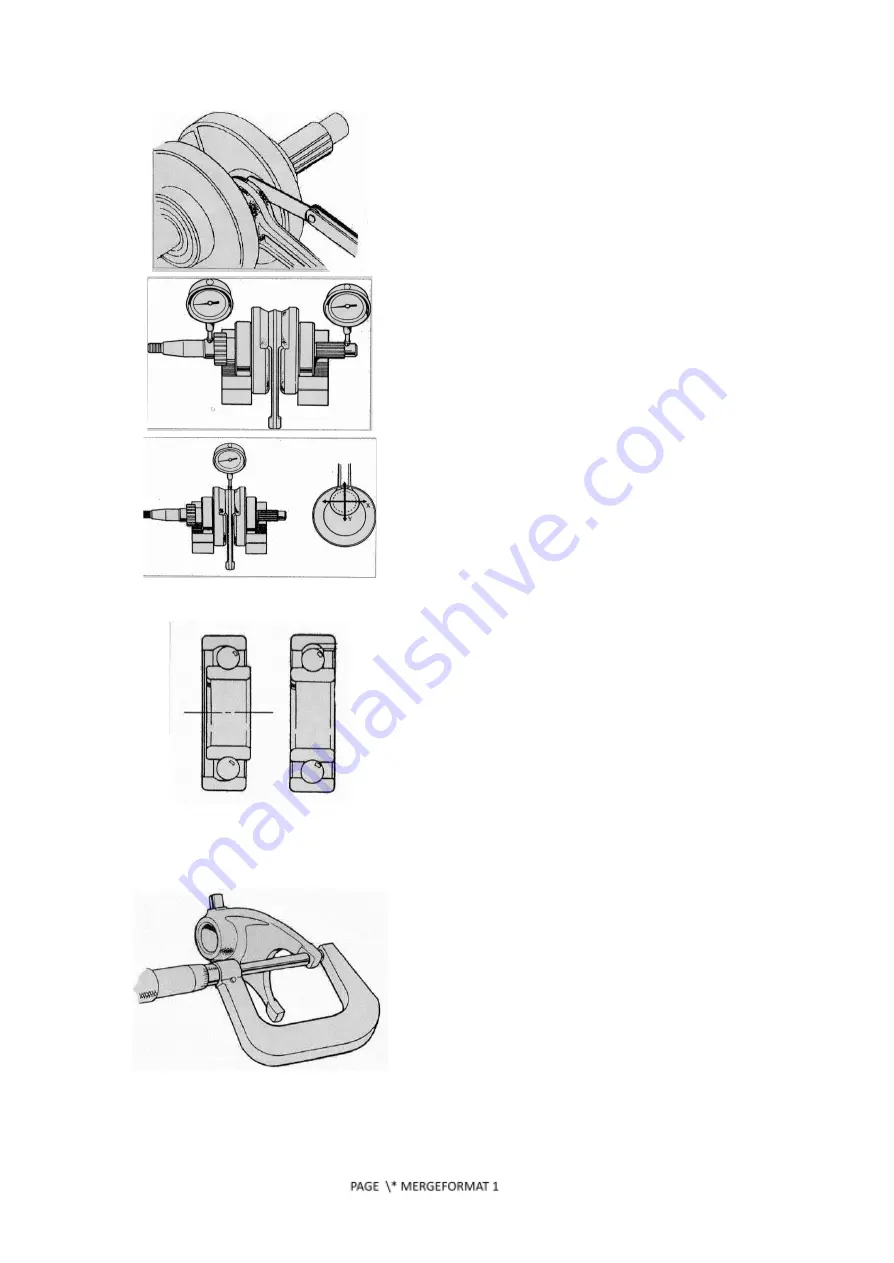

Check the crankshaft as follows:

1. Put the crankshaft on the V-shaped iron, and measure

the large side clearance of the connecting rod with the

thickness gauge. The limit value of maintenance:

0.4mm;

2. Use dial indicator to measure the runout of crankshaft

diameter. Actual runout of the crankshaft

Maintenance limit value: 0.1mm;

3. Measure the radial gap between the two points in the

X and Y direction of the big head of the connecting rod.

Maintenance limit value: 0.015mm;

Left and right crankshaft box bearing inspection

Check the left and right crankshaft box bearings as

follows:

1. Check whether all bearings of the left and right boxes

rotate flexibly; If the rotation is not flexible or there is a

hairpin phenomenon, the bearing of the same type

should be replaced;

2. Take down the left and right boxes of the crankshaft

bearing to check its diameter jump and end jump, if

there is noise or diameter jump and end jump, it should

be replaced with a new crankshaft bearing;

3. Check whether the oil channels of the left and right

containers are smooth.

Check shift fork, fork shaft and shift drum

Check the shift fork, fork shaft and speed drum as

follows:

1. Check whether the shift fork is worn, bent or any

other fault, and measure the inside diameter of the shift

fork;

Fork maintenance limit value: φ 34.031mm

2. Measure the thickness of the fork;

Maintenance limit value: 4.5mm

3. Check the surface and groove of the gear drum for

wear or damage.

Check the combination of main and auxiliary

shafts