KPS SERIES

Technical

Documentation

M-UK-KPS--06

11/02/03 Page 120 of 138

KALTENBACH

6.2.12

Drills General Information

Next to the important fact of having a suitable drilling machine, it is even more

important to have the right drills with the correct method of grinding.

A high-quality drill, which has been grinded in the correct way, possesses / brings the

following features:

-

a nice and clean surface of the hole

-

a round- shaped hole (not triangular)

-

minimum amounts of (small) chips

-

long usage-time

-

optimum feed rates possible (gain in the production)

-

optimum cutting speed (gain in the production)no drill-resonance

-

Short chips

6.2.13

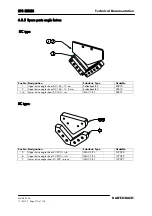

Drill Types and qualities

The best drills to purchase for drilling steel profiles are normal spiral drills; these should

have the quality HSS or better.

For the optimum lubrication and cooling of the drills, it is recommended to use drills

with internal cooling channels. When using this type of drill, it has to be made sure

that the drilling machine is suitable and has a facility for these tools, e.g. a micro

dosage system.

Advantages of using the drills with cooling channels are:

-

longer usage-time of the drill

-

better holes in the profiles

-

no pollution of work or environment (because of mist cooling)

NOTICE

When the drills with cooling channels are not used, the dosage

system should be switched off.

Summary of Contents for KPS Series

Page 1: ...MANUAL KPS 515 Serial No 2008 01 14564...

Page 2: ......

Page 6: ...KPS SERIES Contents M UK KPS 06 11 02 03 Page 6 of 138 KALTENBACH 7 Appendix 138...

Page 136: ......

Page 263: ......

Page 264: ......

Page 265: ......

Page 266: ......

Page 267: ......