2. Wipe off the dipstick with a lint-free cloth or rag and screw the plug fully in again.

3. Unscrew and withdraw the plug once more and read off the oil level on the dipstick.

Oil level at the upper third of the dip stick: Oil level is correct.

If oil does not reach this level: Immediately replenish tool oil.

4. Close the door.

Filling and topping up with tool lubricator oil

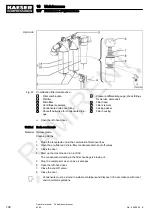

1. Slowly unscrew and withdraw the oil filler plug.

2. Use a funnel to pour in the oil to the maximum level (10 – 15 mm below the top of the tank).

3. Check the oil level.

4. Check the filler plug O-ring for external damage.

Skadet O-ring: replace the O-ring.

5. Insert the plug in the filler port.

6. Close the door.

Further information See chapter 2.8.1.1 for suitable oil grade and volume.

10.7.2 Option da, db, dc, dd

Cyclone separator maintenance

Clean the cyclone separator dirt trap if the moisture content in the compressed air is too high.

Material Cleaning cloth

Wrench

Small screwdriver

Dirt trap maintenance kit

Petroleum ether or spirit

Precondition The machine is shut down.

Machine is cooled down.

The machine is fully vented, the pressure gauge reads 0 bar.

All compressed air consumers are disconnected and the air outlet valves are open.

The negative cable to the battery is disconnected.

10 Maintenance

10.7 Maintenance of Optional Items

No.: 9_5898 26 E

Operator manual Portable compressor

M 64

141

RAMIRENT