1

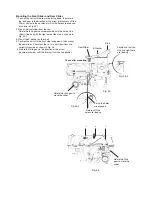

Third Gear

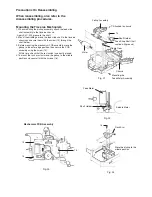

Main PCB

Assembly

Feed Motor

Assembly

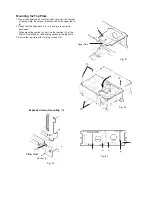

1

2

2

2

3

CN502

CN501

Unsolder

Lifter Bracket (L)

Fig. 49

Fig. 50

Tray Motor

Assembly

Unsolder

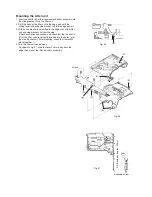

Traverse

Mechanism

PCB Assembly

Grounding Point

Fig. 51

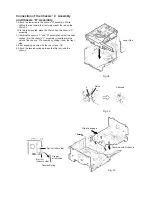

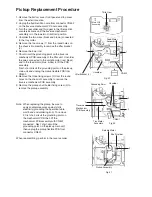

Pickup Assembly

Shaft Holder

Spindle Motor

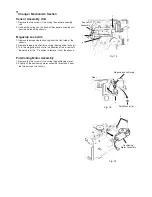

Pickup Replacement Procedure

Note: When replacing the pickup, be sure to

apply countermeasures against static

electricity (grounding the operation table,

wrist band and soldering iron). To remove

it, first short-circuit the grounding point on

the mechanism PCB, then lift the

mechanism PCB assembly with CN501

connected. Next, short-circuit the

grounding point on the pickup main unit,

then unplug the pickup flexible PCB from

connector CN501.

When reassembling, perform in the reverse order.

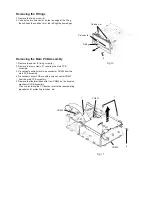

1. Remove the bottom cover, front panel and top cover

from the exterior section.

2. Unplug the flexible ribbon wire from connector CN502

on the traverse mechanism PC board assembly.

3. Turn the rear slider and third gear in the lifter section

counterclockwise until the traverse mechanism

assembly is in the lowermost (bottom) position.

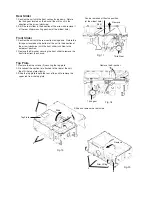

4. Unsolder the two wires (black and brown) connected

to the tray motor.

5. Remove the two screws (1) from the round holes on

the chassis R assembly to remove the lifter bracket

(L).

6. Remove the lower rod.

7. Short-circuit the grounding point on the traverse

mechanism PCB assembly of the lifter unit. Unsolder

the wires connected to the spindle motor (red, black)

and to the feed motor (blue, white) to lift the PCB

assembly.

Next, short-circuit the grounding point on the pickup

main unit and unplug the pickup flexible PCB from

CN501.

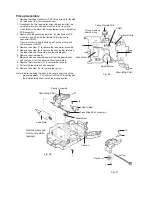

8. Remove the three fixing screws (2) from the round

holes on the chassis R assembly to remove the

traverse mechanism PCB assembly.

9. Remove the pickup shaft holder fixing screw (3) to

remove the pickup assembly.

Summary of Contents for CH-X200

Page 1: ......

Page 19: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 36: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ...Packing Materials and Accessories Parts List Block No M3MM Block No M4MM ...

Page 44: ......

Page 45: ......