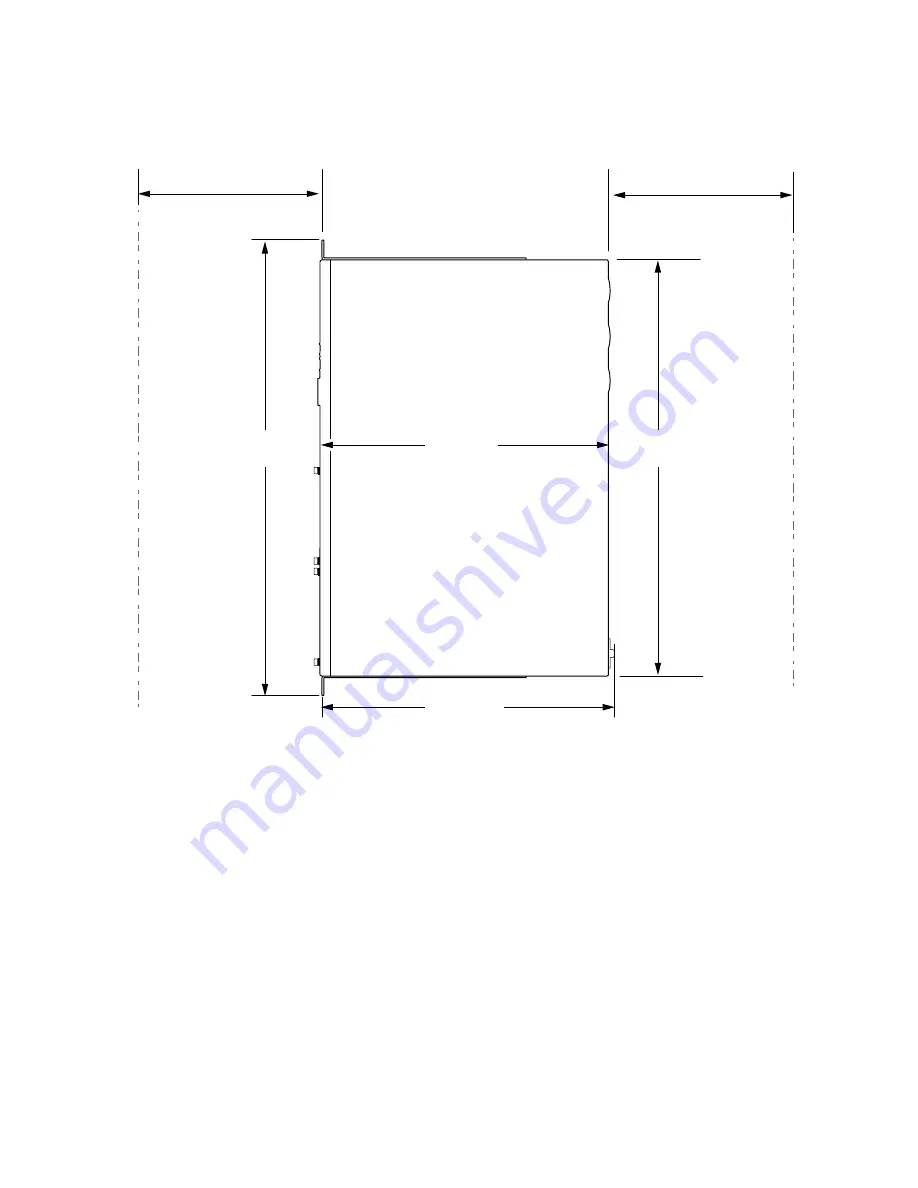

Figure 8: Clearance Requirements for Airflow and Hardware Maintenance for a CTP151 Device

g100907

Front

(Ports)

Rear

19.0 in.

(48.26 cm)

17.36 in.

(44.08 cm)

12.0 in.

(30.51 cm)

12.19 in.

(30.95 cm)

Clearance required

for maintenance

24 in. (61 cm)

Clearance required

for maintenance

24 in. (61 cm)

•

For the cooling system to function properly, the airflow around the chassis must be unrestricted. See

“CTP151 Cooling System” on page 7

for more information about the airflow through the chassis.

•

If you are mounting a CTP151 device in a rack or cabinet with other equipment, ensure that the exhaust

from other equipment does not blow into the intake vents of the chassis.

•

Leave at least 24 in. (61 cm) both in front of and behind the CTP151 device. For service personnel to

remove and install hardware components, you must leave adequate space at the front and back of the

CTP151 device. NEBS GR-63 recommends that you allow at least 30 in. (76.2 cm) in front of the rack

or cabinet and 24 in. (61 cm) behind the rack or cabinet.

RELATED DOCUMENTATION

22

Summary of Contents for CTP151 Platform

Page 1: ...Juniper Networks CTP151 Circuit to Packet Platform Hardware Guide Published 2020 02 07...

Page 12: ...1 PART Overview CTP151 Platform Overview 3 CTP151 Interface Modules 9...

Page 13: ......

Page 26: ......

Page 50: ......

Page 58: ......

Page 71: ...CTP151 Platform Overview 3 63...

Page 78: ......

Page 88: ......

Page 100: ...7 PART Troubleshooting Troubleshooting Hardware and Power Failures 97...

Page 101: ......