−

1

−

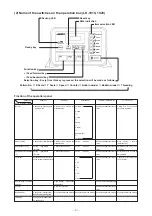

1. SPECIFICATIONS

Specifications

Sewing area

Max. sewing speed

Stitch length

Feed motion of work

clamp foot

Needle bar stroke

Needle

Lift of feeding frame

Hook

Intermediate presser stroke

Lift of intermediate presser

Lubricating oil

Memory of pattern data

Enlarging/Reducing facility

Temporary stop function

Thread breakage

detection function

Enlarging/Reducing method

Max. sewing speed limitation

Pattern selection

Bobbin thread counter

Memory back-up

2nd origin setting facility

Needle-up stop facility

Sewing machine motor

Dimensions

Weight

Power consumption

Operating temperature

range

Operating humidity range

Line voltage

Air pressure used

Air consumption

Needle bar reverse

rotation stop function

* Reduce the max. sewing speed in accordance with the sewing conditions.

LK-1910

LK-1920

0.1 to 10.0 mm (adjustable in 0.1 mm step)

20% to 200% (1% step)

Increasing/decreasing the stitch length method.

The max. sewing speed can be set limited to any

value within a range of 200 to 2,500 rpm using the

up/down key. (100 rpm steps)

Machine head 46 kg, Control box 16.5 kg

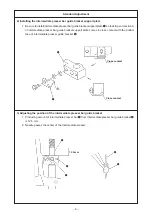

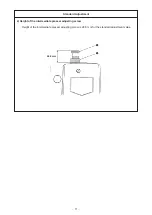

X (lateral) direction 100 mm Y (longitudinal) direction 60 mm

* 2,500 rpm (When sewing pitch is less than 3 mm.)

Intermittent feed (2-shaft drive by stepping motor)

41.2 mm

DPx5, DPx17

Standard 18 mm Max. 22 mm (Pneumatic type : max. 25 mm)

2-fold semi-rotary hook (oil wick lubrication)

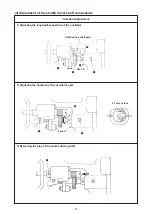

Standard 4 mm (Adjustable in the range of 0 and 4 to 10 mm)

18 mm

New Defrix Oil No. 2 (equivalent to ISO VG 32) (supplied by oiler)

EEP-ROM (32k byte)

Allows a pattern to be enlarged or reduced on the X axis and Y axis independently when sewing a pattern.

Used to stop machine operation during a stitching cycle

Used to detect needle thread breakage to automatically stop machine.

1 to 99 patterns can be selected by specifying the desired pattern Nos. (In case of EEP-ROM)

Tells the time to replace the bobbin by the bobbin thread counter. (Max. 9,999 pcs.)

In case of a power interruption, the pattern being used will automatically be stored in memory.

400W servo motor

W : 1,200 mm L : 700 mm H : 1,160 mm (Use the standard table and stand.)

600 W

5˚C to 35˚C

35% to 85% (No dew condensation)

Rated voltage

±

10% 50/60 Hz

0.5 to 0.55 MPa (5 to 5.5 Kg/cm

2

) (For pneumatic type only)

1.3 R/min (For pneumatic type only)

After the completion of sewing, the needle can be stopped in its upper position by rotating the needle bar

in the reverse direction.

LK-1930

0.1 to 12.7 mm (adjustable in 0.1 mm step)

3.5 inch micro floppy disk (2DD, 2HD)

Memory pattern : 44 to 691 patterns

1% to 400% (1% step)

Increasing/decreasing stitch length or the number of

stitches can be selected.

The max. sewing speed can be set limited to any

value within a range of 200 to 2,500 rpm using the

external variable resistor.

1 to 999 patterns can be selected by specifying the

desired pattern Nos.

(In case of floppy disk)

Using the jog switch, a 2nd origin (needle position after a

sewing cycle) can be set in the desired position within the

sewing area. The set 2nd origin is also stored in memory.

When the needle does not stop in its upper position,

the needle can be brought up to the upper position by

turning again the needle threading switch.

Machine head 46 kg, Control box 18 kg