– 25 –

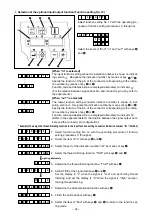

The producton support functon conssts of three dfferent functons (sx dfferent modes) such as the produc-

ton volume management functon, operaton measurng functon and bobbn counter functon. Each of them

has ts own producton support effect. Select the approprate functon (mode) as requred.

■

Production volume management function

Target No. of pcs. dsplay mode [F00]

Target/actual No. of pcs dfference dsplay mode [F200]

The target number of peces, actual number of peces and the dfference between the target and actual

number of peces along wth the operaton tme are dsplayed to notfy the operators of a delay and ad-

vance n real tme. Sewng machne operators are allowed to engage sewng whle constantly checkng

hs/her work pace. Ths helps rase target awareness, thereby ncreasng productvty. In addton, a delay

n work can be found at an early stage to enable early detecton of problems and early mplementaton of

correctve measures.

■

operation measuring function

Sewng machne avalablty rate dsplay mode [F300]

Ptch tme dsplay mode [F400]

Average number of revolutons dsplay mode [F500]

Sewng machne avalablty status s automatcally measured and dsplayed on the control panel. The

data obtaned can be used as basc data to perform process analyses, lne arrangement and equpment

efficiency checkup.

■

Bobbin counter function

Bobbn counter dsplay mode

In order to change bobbns before the current bobbn runs out of thread, the tme for replacng the bob-

bin is notified.

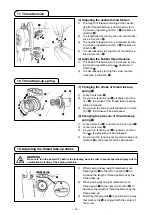

[to use the production support mode]

Keep

swtch

7

held pressed (one second) n

the normal sewng state to call the one-touch settng

screen.

Then, press

swtch

1

or

swtch

2

to set

each producton support mode n ON/OFF state to

call the one-touch settng screen.

Press

swtch

3

or

swtch

4

to select the

mode to be set n the ON/OFF state.

ON/OFF of the dsplay can be changed over by

pressng

swtch

5

or

swtch

6

.

To return to the normal sewng state, press

swtch

7

.

(caution) Modes F100 to F500 have been factory-

set in the oFF state at the time of delivery.

the mode state is changed over to oN/oFF ac-

cording to the setting of the bobbin thread coun-

ter function (function setting No. 6).

6

5

4

3

7

2

1

5. Production support function