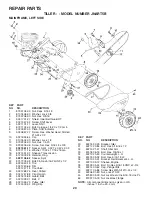

22

KEY

PART

NO.

NO.

DESCRIPTION

NOTE:

All component dimensions given in U.S. inches.

1 inch = 25.4 mm

1

532 18 06-77

Transmission Assembly

(Includes Key Nos. 2-53)

2

532 18 06-27

Gearcase, L.H. w/Bearing

(Includes Key No. 4)

3

532 16 19-63 Gasket, Gearcase

4

532 00 50-20 Bearing, Needle

5

532 00 13-70 Washer, Thrust 5/8 x 1.10 x 1/32

6

532 13 73-35 Pinion, Input

7

532 14 51-01 Shaft, Input

8

532 12 47-92 Bearing, Needle

9

532 15 44-67 Washer, Seal

10

532 12 46-97 Ball, Steel

11

532 10 03-71 Spring, Shift, Fork

12

532 10 61-60 O-Ring

13

532 14 21-45 Arm, Shift

14

532 00 83-53 Fork, Shift

15

812 00 00-39 Ring, Klip

16

532 15 44-66 Shaft, Shift

18

532 00 43-58 Washer

19

812 00 00-40 Ring, Klip

20

532 10 21-14 Gear, Assembly, Reverse Idler

(Includes Key Nos. 21 and 22)

21

532 10 21-15 Gear, Reverse Idler

22

532 00 68-03 Bearing, Needle

23

532 10 21-11 Shaft, Reverse Idler

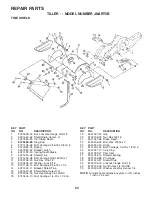

REPAIR PARTS

TILLER - - MODEL NUMBER JNART5B

TRANSMISSION

KEY

PART

NO.

NO.

DESCRIPTION

24

810 04 07-00 Washer, Lock 7/16

25

873 61 07-00 Nut, Hex 7/16-20

27

532 14 30-09 Bearing, Shaft, Ground Drive L.H.

28

532 10 63-90 Spacer 0.765 x 1.125 x 1.23

29

532 10 21-34 Chain #35-50 Pitch

30

532 15 07-37 Ground Shaft Assembly

31

532 14 30-08 Bearing, Shaft, Ground Drive R.H.

32

532 10 63-88 Spacer 0.70 x 1.00 x 1.150

33

532 10 21-21 Sprocket and Gear Assembly

34

532 10 21-12 Shaft, Reduction (2nd)

35

532 10 21-01 Screw, Whiz, Lock 5/16-18 x 3-1/2

36

532 15 43-55 Sprocket Assembly w/Bearing

(Includes Key Nos. 37 and 38)

37

532 12 47-91 Bearing, Needle

38

532 15 43-56 Sprocket, Tine

39

532 10 53-45 Gear, Cluster, Red 1st & 2nd

40

532 10 53-46 Gear, Reverse

41

532 00 83-58 Shaft, Reduction (1st)

42

532 00 42-20 Washer, Thrust

43

532 10 61-46 Spacer 1.01 x 1.75 x 0.760

44

532 15 52-36 Seal Asm, Oil

48

532 18 06-31

Gearcase, R.H. w/Bearing

(Includes Key No. 8)

49

532 13 26-88 Shaft, Tine

50

532 10 61-47 Chain, Roller #50-50 Pitch

51

817 72 04-08 Screw 1/4-20 x 1/2

52

873 22 05-00 Nut, Hex 5/16-18

53

532 16 51-40 Kit, Bearing

58

532 17 95-20

Bolt Shoulder

60

532 12 48-36 Fitting Grease

- -

532 00 60-66 Grease, Plastilube #1