Waterbox drain and vent valves

Install drain and vent valves (supplied by others) in the connections provided in the evaporator

liquid heads. These connections can be piped to drain if required. They assist in proper fill and vent

of the chiller waterside before starting pumps to ensure no voids exist that could cause damage

from a water slug.

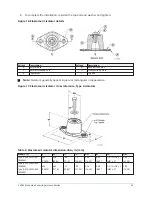

Waterbox fill and vent

After the water piping is completed, but before any waterbox insulation is applied, tighten the nuts

on the liquid head flanges. Torque to maintain between 30 ft·lb and 60 ft·lb (41 N•m and 81 N•m).

Gasket shrinkage and handling during transit can cause the nuts to loosen. If water pressure is

applied before tightening is completed, the gaskets might be damaged and have to be replaced.

Fill the chilled water circuit, operate the pumps manually, and carefully check the evaporator water

heads and piping for leaks. Repair leaks as necessary.

Before initial operation of the unit, thoroughly vent the chilled water circuit of all air at the high

points.

Wiring connections

Unit power wiring

The factory mounted Variable Speed Drive does not require wiring to the compressor motor.

The motor power wiring is factory connected to the Variable Speed Drive. Refer to the

YVAM Unit

Wiring and Field Control Modifications Manual (Form 160.88-PW2)

. All wiring to the control panel is

completed by the factory. A control power transformer is factory furnished with the Variable Speed

Drive.

Power wiring to the chiller is made through the single point power connection enclosure. Refer to

Field connections diagram for Model YVAM Single Point Power Connection Manual (Form 160.88-PW1)

for

details.

CAUTION

Do not cut wires to final length or make final connections to the chiller power input terminals without

supervision from a qualified Johnson Controls representative.

Unit control wiring

If field wiring connections for commonly encountered control modifications (by others) are

required, refer to the

YVAM Unit Wiring and Field Control Modifications Manual (Form 160.88-PW2)

for

details.

Note:

No deviations in unit wiring from that shown on drawings furnished will be made

without prior approval of the Johnson Controls representative.

Apply insulation

All evaporator parts are factory insulated on the shell surfaces, end sheets, liquid feed line to flow

chamber, compressor suction connection, and evaporator liquid heads and water connection

nozzles.

All facility chilled water piping surfaces must be insulated (by others) to prevent condensation

from causing any type of operational heat loss or component damage on all piping upstream and

downstream of the chilled water evaporator waterbox nozzles.

27

YVAM Air-Cooled Centrifugal Liquid Chiller