There is no intent for the user to perform any maintenance tasks on the HVAC unit.

D A N G E R

It is strictly prohibited for the user to carry out any maintenance or upkeep tasks on the HVAC unit.

This appliance is not destined for use by people (including children) with limited physical, sensorial or

mental capacities, or without adequate experience or knowledge, unless they have received instructions

or been supervised in the use of the appliance by an individual responsible for their safety.

Children must be supervised at all times to ensure that they do not play with the appliance.

Only trained Johnson Controls Inc. personnel with the necessary means and tools may carry out

maintenance and upkeep work on the unit.

Trained personnel must be aware of the health and safety regulations and procedures applicable to

HVAC units. They should also be aware of general procedures and those applying specifically to this

unit.

Contact a Johnson Controls Inc. Authorised Technical Assistance Service for scheduled maintenance

on this unit.

PRODUCT DISPOSAL

According to Directive 2002/96/EC of the European

Parliament and of the Council of 27 January 2003, the

presence of the symbol on the product or in the

documents included with the product indicates that

this product is classified, according to current law, as

an electrical and electronic device and, therefore, this

product cannot be dealt with at the end of its working

life as domestic or urban waste.

The product must be taken to collection points for the

recycling of waste electrical and electronic

equipment.

The appropriate management, reuse, assessment

and recycling of these products protect human health and the environment.

User manual

1

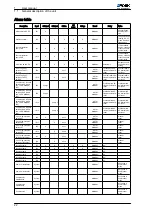

General description of the unit

1.1

25