1183746-UIM-D-1015

6

Johnson Controls Unitary Products

DUCTWORK

These units are adaptable to downflow use as well as rear supply and

return air duct openings. To convert to downflow, use the following

steps:

1.

Remove the duct covers found in the bottom return and supply air

duct openings.

2.

Install the duct covers (removed in step one) to the rear supply and

return air duct openings.

3.

Seal duct covers with silicone caulk.

Duct work should be designed and sized according to the methods of

the Air Conditioning Contractors of America (ACCA), as set forth in their

Manual D.

A closed return duct system shall be used. This shall not preclude use

of economizers or ventilation air intake. Flexible joints are recom-

mended to be used in the supply and return duct work to minimize the

transmission of vibration and noise.

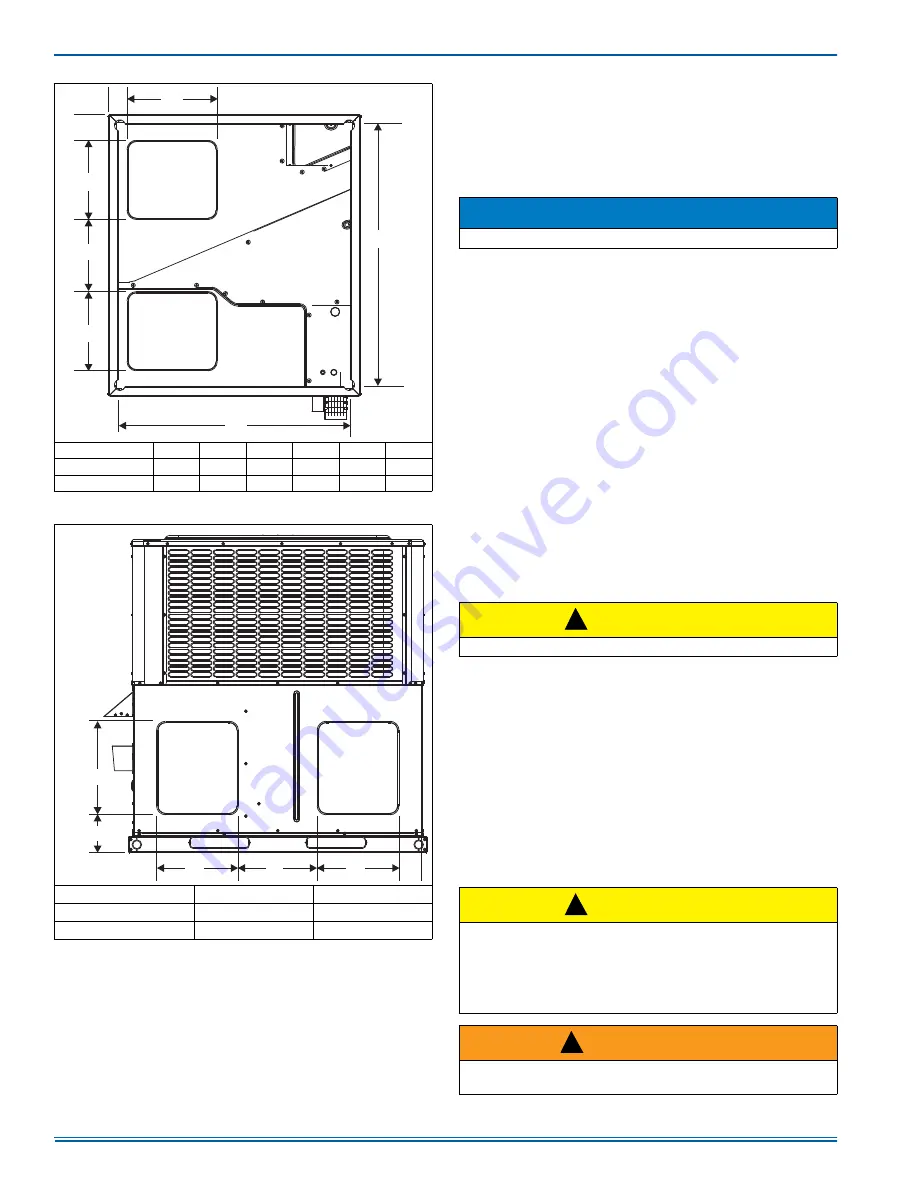

Refer to Figures 5 and 6 for information concerning rear and bottom

supply and return air duct openings.

FILTERS

Proper filter size is very important. Filter size, type and pressure drop

should always be considered during duct system design.

Single phase units are shipped without a filter or filter racks. It is the

responsibility of the installer to secure a filter in the return air ductwork

or install a Filter/Frame Kit.

A filter rack and high velocity filters are standard on three phase units.

Filters must always be used and must be kept clean. When filters

become dirt laden, insufficient air will be delivered by the blower,

decreasing your units efficiency and increasing operating costs and

wear-and-tear on the unit and controls.

Filters should be checked monthly; this is especially important since this

unit is used for both heating and cooling.

CONDENSATE DRAIN

A condensate trap must be installed in the condensate drain. The

plumbing must conform to local codes.

DO NOT use Teflon tape or Pipe thread compound.

SERVICE ACCESS

Access to all serviceable components is provided at the following loca-

tions:

• Coil guards

• Unit top panel

• Corner posts

• Blower access panel

• Control access panel

• Indoor coil access panel

• Compressor access panel

• Heat exchanger access panel

Refer to Figure 4 for location of these access locations and minimum

clearances in Table 4.

Refer to Figure 14 for the R-410A Quick Reference Guide.

Model

A

B

C

D

E

F

24, 30, 36, 42

10

21.5

5

4.5

47.5

32

48, 60

14

13.5

5

3.5

47.5

42

FIGURE 4:

Bottom Duct Dimensions (inches)

Model

A

B

24, 30, 36, 42

9.6

22

48, 60

13.6

14

FIGURE 5:

Rear Duct Dimensions (inches)

D

16

C

A

B

A

A0298-001

SUPPLY

AIR DUCT

RETURN

AIR DUCT

F

E

15.6

A

B

A

4.3

A0299-001

6

SUPPLY

AIR DUCT

RETURN

AIR DUCT

NOTICE

Be sure to note supply and return openings.

CAUTION

Hand tighten only.

CAUTION

This system uses R-410A Refrigerant which operates at higher pres-

sures than R-22. No other refrigerant may be used in this system.

Gage sets, hoses, refrigerant containers and recovery systems must

be designed to handle R-410A. If you are unsure, consult the equip-

ment manufacturer. Failure to use R-410A compatible servicing

equipment may result in property damage or injury.

WARNING

Wear safety glasses and gloves when handling refrigerants. Failure

to follow this warning can cause serious personal injury.

!

!

!