4

PERIODIC MAINTENANCE AND SERVICE

General

The following checklist is provided as an abbreviated

guide to periodic maintenance. Detailed procedural in-

formation is given after this checklist.

After 48 Hours of Operation

Belts will achieve their permanent stretch and will re-

quire re-adjustment, make sure not to over-tighten. See

for adjustment instructions.

Weekly

Observe unit weekly for any changes in running condi-

tion and unusual noise.

Every Month

• Check air filters. Clean or replace if clogged or

dirty.

•

Re-lubricate fan bearings if operating conditions

include high speeds, moist or dirty air, or high

temperatures.

•

Re-lubricate motor bearings in accordance with

motor manufacturer’s recommendations if operat-

ing conditions include high speed, moist or dirty

air, or high temperatures. See motor label (

.

•

Check and adjust fan belt tension.

Every Three to Six Months

•

Check fan bearing grease line connections. Lines

should be tight to the bearings.

•

Re-lubricate fan bearings.

•

Check motor lubrication. Recommendations are

provided on the motor label.

•

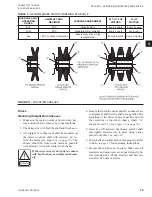

Check bearing and motor bracket bolt torque (see

).

•

Align fan and motor sheaves. Tighten sheave set-

screws to the proper torque (see

•

Check and adjust fan belt tension.

•

Tighten electrical connections

•

Inspect coils for dirt build-up or coil freeze-up.

Every Year

•

Inspect the units casing for corrosion. If damage

is found, clean and paint the surface with a rust-

resistant primer and vinyl chlorinated lacquer.

•

Clean the fan wheel and fan shaft. Remove rust

with an emery cloth and apply a coat of heavy

duty rust inhibitor.

• Clean the coils. Using a fin comb straighten any

bent fins.

•

Inspect the condensate pan and drain line; remove

sludge or foreign materials that might obstruct

proper drainage. Remove obstructions.

•

Check damper linkages, set screws and blade ad-

justment. Clean, but do not lubricate, the nylon

damper rod bushings.

•

Clean damper operators.

•

Inspect the control and power box wiring for se-

cure connections and insulation.

•

Rotate the fan wheel and check for obstructions

in the fan housing. The wheel should not rub on

the fan housing. Adjust the wheel to center if nec-

essary and tighten wheel setscrews to the proper

).

•

Check condition of gasketing and insulation

around unit, door and dampers. Repair or replace

as necessary.

• Examine flex connections for cracks or leaks. Re

-

pair or replace damaged material.

SECTION 4 - PERIODIC MANINTENANCE AND SERVICE

JOHNSON CONTROLS

21

FORM ET102.19-NOM1

ISSUE DATE:08/26/2013