SECTION 3 - CHASSIS & TURNTABLE

3-20

– JLG Lift –

3121290

3.3

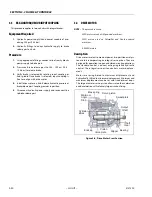

RE-ALIGN TORQUE HUB INPUT COUPLING

This procedure applies to torque hubs with integral brakes:

Equipment Required

1.

Hydraulic power supply (hand pump) capable of pro-

ducing 200 psi (13.8 bar).

2.

Hydraulic fittings to adapt hydraulic supply to brake

release port on hub.

Procedure

1.

Using appropriate fittings, connect a line from hydraulic

power supply to brake port.

2.

Pressurize brake release port to 155 - 200 psi (10.6 -

13.8 bar) to release brake.

3.

Verify brake is released by rotating input coupling or

hub spindle. Once brake is released, input coupling is

free to re-align with drive motor.

4.

Install drive motor on hub. Release hydraulic pressure at

brake release port. Coupling remains in position.

5.

Disconnect hydraulic power supply and reconnect line

to brake release port.

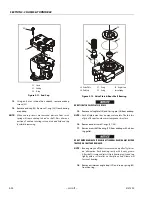

3.4

DRIVE MOTOR

NOTE:

This procedure covers:

2WD motors used on GM powered machines.

2WD motors used on Caterpillar and Deutz powered

machines.

All 4WD motors.

Description

Drive motors are low to medium power, two-position axial pis-

ton motors incorporating an integral servo piston. They are

designed for operation in open and closed circuit applications.

The standard control is a direct acting single line hydraulic

control. The integral servo piston controls motor displace-

ment.

Motors are spring biased to maximum displacement and

hydraulically shifted to minimum displacement. Minimum and

maximum displacement can be set with fixed internal stops.

The large diameter servo piston allows smooth acceleration

and deceleration with relatively large circuit orificing.

Figure 3-6. Drive Motor Cross Section

Bias spring

Servo piston

Swashplate

Output

Shaft

Piston

Slipper

Cylinder

Block

Endcap

Shaft

Seal

Bearing

Minimum

Angle

Stop

Valve plate

Summary of Contents for 450A II Series

Page 46: ...SECTION 3 CHASSIS TURNTABLE 3 6 JLG Lift 3121290 Figure 3 4 Drive Hub 4WD Front Only ...

Page 79: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 39 Figure 3 32 Swing Bearing Drive ...

Page 101: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 61 Figure 3 42 Auxiliary Pump ...

Page 113: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 73 Figure 3 53 EMR2 Fault Codes Sheet 1 of 5 ...

Page 114: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121290 Figure 3 54 EMR2 Fault Codes Sheet 2 of 5 ...

Page 115: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 75 Figure 3 55 EMR2 Fault Codes Sheet 3 of 5 ...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 76 JLG Lift 3121290 Figure 3 56 EMR2 Fault Codes Sheet 4 of 5 ...

Page 117: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 77 Figure 3 57 EMR2 Fault Codes Sheet 5 of 5 ...

Page 159: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 119 ...

Page 161: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 121 ...

Page 163: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 123 ...

Page 165: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 125 ...

Page 173: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 133 Sensor Transducer Type ...

Page 177: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 137 Sensor Transducer Type ...

Page 179: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 139 ...

Page 181: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 141 ...

Page 183: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 143 ...

Page 185: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 145 ...

Page 187: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 147 ...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 163 ...

Page 207: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 167 ...

Page 217: ...SECTION 4 BOOM PLATFORM 3121290 JLG Lift 4 5 Figure 4 2 Boom Limit Switches ...

Page 310: ...SECTION 5 HYDRAULICS 5 70 JLG Lift 3121290 NOTES ...

Page 312: ...SECTION 6 JLG CONTROL SYSTEM 6 2 JLG Lift 3121290 Figure 6 2 Controller Block Diagram 0 ...

Page 370: ...SECTION 6 JLG CONTROL SYSTEM 6 60 JLG Lift 3121290 NOTES ...

Page 394: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 24 JLG Lift 3121290 NOTES ...

Page 395: ......