SECTION 3 - CHASSIS & TURNTABLE

3-60

– JLG Lift –

3121290

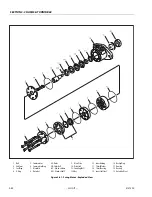

Two Piece Stator Assembly

A disassembled rotor set (8) that cannot be easily by hand and

has a two piece stator, can be assembled using the following

procedures:

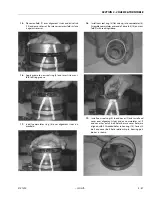

1.

Place stator half on wear plate (9) with seal ring (4) side

down, after following motor assembly procedures 1

through 13. Be sure seal ring is in place.

2.

Align stator bolt holes with wear plate and

housing bolts. Turn two alignment studs

finger tight in bolt holes approximately 180° apart to

keep stator half and wear plate stationary.

3.

Assemble rotor, counterbore down if applicable, into

stator half, and onto wear plate (9) with rotor splines

into mesh with drive link (10) splines.

NOTE:

Use marking applied to rotor set components to reassem-

ble components in their original relationship to ensure ulti-

mate wear life and performance.

4.

Assemble six vanes, or as many vanes that readily

assemble into stator vane pockets.

EXCESSIVE FORCE USED TO PUSH ROTOR VANES IN PLACE COULD SHEAR OFF

COATING APPLIED TO STATOR VANE POCKETS.

5.

Grasp output end of coupling shaft (12) with

locking pliers or other appropriate turning device and

rotate coupling shaft, drive link and rotor to seat rotor

and assembled vanes (8C) into stator half, creating nec-

essary clearance to assemble seventh or full comple-

ment of seven vanes. Assemble the seven vanes using

minimum force.

6.

Place second stator half on a flat surface with seal ring

groove up. Apply a small amount of grease to a new seal

ring (4) and install it in stator half ring groove.

7.

Assemble second stator half over two alignment studs

and rotor with seal ring side down onto the first stator

half aligning any timing marks applied for this purpose.

IF STATOR HALF (8B) IS A DIFFERENT HEIGHT (THICKNESS) THAN STATOR

HALF (8D) STATOR VANES (8C) OR (8E)OF THE SAME LENGTH (HEIGHT) AS STA-

TOR HALF MUST BE REASSEMBLED IN THEIR RESPECTIVE STATOR HALF FOR

ROTOR SET TO FUNCTION PROPERLY.

8.

Assemble six vanes, or as many vanes that readily

assemble into stator vane pockets.

9.

Grasp output end of coupling shaft (12) with locking pli-

ers or other appropriate turning device and rotate cou-

pling shaft, drive link, and rotor to seat rotor and

assembled vanes into stator, creating necessary clear-

ance to assemble seventh or full complement of seven

vanes. Assemble seven vanes using minimum force.

Go to Step 14 on page 3-56 to continue assembly.

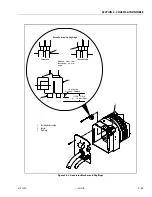

Final Checks

1.

Pressurize motor with 100 psi dry air or nitrogen and

submerge in solvent to check for external leaks.

2.

Check motor for rotation. Torque required to rotate cou-

pling shaft should not be more than 50 ft-lb (68 Nm).

3.

Pressure port with “A” cast under it on housing (18) is for

clockwise coupling shaft rotation as viewed from the

output end of coupling shaft. Pressure port with “B” cast

under it is for counter clockwise coupling shaft rotation.

4.

Use test stand and check motor operation.

Installation

Refer to Figure 3-40., Swing Motor Removal and Installation.

1.

Carefully insert swing motor into swing drive, making

sure swing motor shaft key is aligned correctly.

2.

Secure swing motor to swing drive assembly with two

bolts and flat washers. Apply JLG threadlocker P/N

0100019 to threads of retaining bolts. Torque to 85 ft-lb

(115 Nm).

3.

Connect hydraulic lines running to swing motor as

tagged during removal.

TORQUE

Summary of Contents for 450A II Series

Page 46: ...SECTION 3 CHASSIS TURNTABLE 3 6 JLG Lift 3121290 Figure 3 4 Drive Hub 4WD Front Only ...

Page 79: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 39 Figure 3 32 Swing Bearing Drive ...

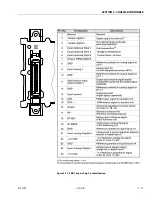

Page 101: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 61 Figure 3 42 Auxiliary Pump ...

Page 113: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 73 Figure 3 53 EMR2 Fault Codes Sheet 1 of 5 ...

Page 114: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121290 Figure 3 54 EMR2 Fault Codes Sheet 2 of 5 ...

Page 115: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 75 Figure 3 55 EMR2 Fault Codes Sheet 3 of 5 ...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 76 JLG Lift 3121290 Figure 3 56 EMR2 Fault Codes Sheet 4 of 5 ...

Page 117: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 77 Figure 3 57 EMR2 Fault Codes Sheet 5 of 5 ...

Page 159: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 119 ...

Page 161: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 121 ...

Page 163: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 123 ...

Page 165: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 125 ...

Page 173: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 133 Sensor Transducer Type ...

Page 177: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 137 Sensor Transducer Type ...

Page 179: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 139 ...

Page 181: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 141 ...

Page 183: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 143 ...

Page 185: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 145 ...

Page 187: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 147 ...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 163 ...

Page 207: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 167 ...

Page 217: ...SECTION 4 BOOM PLATFORM 3121290 JLG Lift 4 5 Figure 4 2 Boom Limit Switches ...

Page 310: ...SECTION 5 HYDRAULICS 5 70 JLG Lift 3121290 NOTES ...

Page 312: ...SECTION 6 JLG CONTROL SYSTEM 6 2 JLG Lift 3121290 Figure 6 2 Controller Block Diagram 0 ...

Page 370: ...SECTION 6 JLG CONTROL SYSTEM 6 60 JLG Lift 3121290 NOTES ...

Page 394: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 24 JLG Lift 3121290 NOTES ...

Page 395: ......