SECTION 5 -

SECTION 5 - MAST COMPONENTS

MAST COMPONENTS

5-10

5-10

– JLG Lift –

– JLG Lift –

3121228

3121228

Lift Cylinder Component Inspection

Lift Cylinder Component Inspection

Cylinder Rod

Cylinder Rod

There should be no scratches or pits deep enough to

There should be no scratches or pits deep enough to

catch the fingernail. Pits that go to the base metal are

catch the fingernail. Pits that go to the base metal are

unacceptable. Scratches that catch the fingernail but are

unacceptable. Scratches that catch the fingernail but are

not to the base metal, less than

not to the base metal, less than 0.5 inch long and primarily

0.5 inch long and primarily

in the circumferential direction are acceptable provided

in the circumferential direction are acceptable provided

they cannot cut the rod seal.

they cannot cut the rod seal. Chrome should be present

Chrome should be present

over the entire surface of the rod and the lack thereof is

over the entire surface of the rod and the lack thereof is

unacceptable. In the event that an unacceptable condition

unacceptable. In the event that an unacceptable condition

occurs, the rod should be

occurs, the rod should be repaired or replaced.

repaired or replaced.

Cylinder Head

Cylinder Head

Visually inspect the inside bore for

Visually inspect the inside bore for scratches or polishing.

scratches or polishing.

Deep scratches are unacceptable. Polishing indicates

Deep scratches are unacceptable. Polishing indicates

uneven loading and when this occurs,

uneven loading and when this occurs, the bore should be

the bore should be

checked for

checked for out-of-ro

out-of-roundness. If

undness. If out-of-roun

out-of-roundness

dness

exceeds 0.007", this is unacceptable. Check the

exceeds 0.007", this is unacceptable. Check the condition

condition

of the dynamic seals (wiper, rod seals) looking particularly

of the dynamic seals (wiper, rod seals) looking particularly

for metallic particles embedded in the seal surface. It is

for metallic particles embedded in the seal surface. It is

normal to cut the static seal

normal to cut the static seal on the retaining ring groove

on the retaining ring groove

upon disassembly. Remove the rod seal, static o-ring and

upon disassembly. Remove the rod seal, static o-ring and

backup and rod wiper. Damage to the seal grooves, par-

backup and rod wiper. Damage to the seal grooves, par-

ticularly on the sealing surfaces, is unacceptable. In the

ticularly on the sealing surfaces, is unacceptable. In the

event that an

event that an unacceptab

unacceptable condition occurs, the head

le condition occurs, the head

should be replaced.

should be replaced.

Piston

Piston

Visually inspect the outside surface for scratches or pol-

Visually inspect the outside surface for scratches or pol-

ishing. Deep scratches

ishing. Deep scratches are unacceptable. Polishing indi-

are unacceptable. Polishing indi-

cates uneven loading and when this occurs, the diameter

cates uneven loading and when this occurs, the diameter

should be checked for out-of-roundness. If out-of-round-

should be checked for out-of-roundness. If out-of-round-

ness exceeds 0.007", this is

ness exceeds 0.007", this is unacceptable. Check the con-

unacceptable. Check the con-

dition of the dynamic seals and bearings looking

dition of the dynamic seals and bearings looking

particularly for metallic particles embedded in the bearing

particularly for metallic particles embedded in the bearing

and in the piston seal surface. Remove the seals and

and in the piston seal surface. Remove the seals and

bearings. Damage to the seal grooves, particularly on the

bearings. Damage to the seal grooves, particularly on the

sealing surfaces, is unacceptable. In the event that an

sealing surfaces, is unacceptable. In the event that an

unacceptable condition occurs, the piston should be

unacceptable condition occurs, the piston should be

replaced.

replaced.

Tube Assembly

Tube Assembly

Visually inspect the inside bore for scratches and pits.

Visually inspect the inside bore for scratches and pits.

There should be no scratches or pits deep enough to

There should be no scratches or pits deep enough to

catch the fingernail. Scratches that catch the fingernail but

catch the fingernail. Scratches that catch the fingernail but

are less than 0.5 inch long and primarily in the circumfer-

are less than 0.5 inch long and primarily in the circumfer-

ential direction are acceptable provided they cannot cut

ential direction are acceptable provided they cannot cut

the piston seal. The roughness of the bore should be

the piston seal. The roughness of the bore should be

between 10 and 20

between 10 and 20

μ

μ

inches RMS.

inches RMS. Significant variati

Significant variation

on

(greater than 8

(greater than 8

μ

μ

inches difference) are

inches difference) are unacceptab

unacceptable. In

le. In

the event that an

the event that an unacceptable condition occurs, the tube

unacceptable condition occurs, the tube

assembly should be repaired or re

assembly should be repaired or re placed.

placed.

Cylinder Assembly

Cylinder Assembly

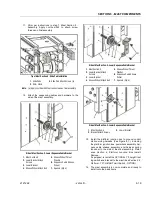

(See

(See Figure 5-3.

Figure 5-3. )

)

1.

1. Rinse

Rinse the in

the inside

side of th

of the tube

e tube with h

with hydrau

ydraulic fl

lic fluid a

uid and

nd

allow to drain. A high-pressure rinse followed by a

allow to drain. A high-pressure rinse followed by a

wipe with a lint-free rag is preferable. Clean all inter-

wipe with a lint-free rag is preferable. Clean all inter-

nal components of any foreign material.

nal components of any foreign material.

2.

2. Lubri

Lubricate

cate the h

the head a

ead and al

nd all sea

l seals wit

ls with hy

h hydraul

draulic fl

ic fluid

uid

prior to installation. Install the seal, wiper, o-ring,

prior to installation. Install the seal, wiper, o-ring,

back-up ring, and retraining ring to the cylinder

back-up ring, and retraining ring to the cylinder

head.

head.

3.

3. Lubri

Lubricate

cate the

the pisto

piston an

n and a

d all c

ll compon

omponents

ents with

with

hydraulic fluid. Install the seal and wear ring to the

hydraulic fluid. Install the seal and wear ring to the

piston.

piston.

NOTE:

NOTE:

Re-check that seals are not twisted or pinched and

Re-check that seals are not twisted or pinched and

are properly seated.

are properly seated.

4.

4. Place

Place the ro

the rod on a

d on a clean t

clean table.

able. Instal

Install the

l the stati

static pis

c pis--

ton o-ring seal into the groove on the piston end of

ton o-ring seal into the groove on the piston end of

the rod.

the rod.

5.

5. Insta

Install th

ll the head

e head foll

followed b

owed by the

y the pist

piston on

on onto th

to the rod

e rod

noting the proper orientation of each component.

noting the proper orientation of each component.

Torque the piston nut to 100-120 ft. lbs.

Torque the piston nut to 100-120 ft. lbs.

6.

6. When

When the ro

the rod ass

d assembly

embly is re

is ready t

ady to be

o be insta

installed

lled into

into

the tube, liberally apply an

the tube, liberally apply an anti-seize lubricant to the

anti-seize lubricant to the

cylinder head surface which slides into the cylinder

cylinder head surface which slides into the cylinder

tube.

tube.

7.

7. Next d

Next dip th

ip the enti

e entire rod

re rod assemb

assembly in

ly into hy

to hydraul

draulic fl

ic fluid

uid

and stuff this assembly into the tube. Watch the

and stuff this assembly into the tube. Watch the

seals as they pass over the rod port

seals as they pass over the rod port

(if visible)

(if visible)

to be

to be

sure they are not nicked or cut.

sure they are not nicked or cut.

8.

8. Insta

Install the h

ll the head un

ead until th

til the retai

e retaining r

ning ring s

ing seats in

eats in it’s

it’s

groove.

groove.