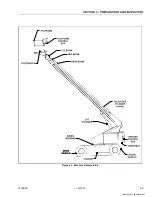

SECTION 2 - PREPARATION AND INSPECTION

3120889

– JLG Lift –

2-7

27.

Muffler and Exhaust System - Properly secured, no

evidence of leakage

28.

Cowling and Latches, Right Side - All cowling and

latches in working condition, properly secured, no

loose or missing part.

29.

Turntable Bearing and Pinion - No loose or missing

hardware; no visible damage, evidence of proper

lubrication. No evidence of loose bolts or looseness

between bearing and structure.

30.

Battery - Proper electrolyte levels; cables tight, no

visible damage or corrosion.

31.

Frame - No visible damage, no loose or missing

hardware (top and underside).

32.

Drive Hub, Left Rear - No visible damage, no evi-

dence of leakage.

33.

Wheel/Tire Assembly, Left Rear - Properly secured,

no loose or missing lug nuts, no visible damage.

34.

Drive Motor and Brake, Left Rear - No visible dam-

age, no evidence of leakage.

35.

Boom Sections - No visible damage; wear pads

secure. All cylinders - rod end shafts and barrel-end

shafts properly secured.

36.

Rotator and Motor - Properly secured, no visible

damage, no evidence of leakage.

37.

Platform Pivot and Slave Cylinder Attach Pins -

Properly secured; evidence of proper lubrication

where applicable.

Figure 2-4. Daily Walk-Around Inspection Points - Sheet 2

Summary of Contents for 100HX

Page 2: ...Courtesy of Crane Market...

Page 4: ...FOREWORD b JLG Lift 3120889 This page left blank intentionally Courtesy of Crane Market...

Page 6: ...FOREWORD d JLG Lift 3120889 REVISON LOG January 1999 Original Issue Courtesy of Crane Market...

Page 78: ...Courtesy of Crane Market...

Page 79: ...Courtesy of Crane Market...