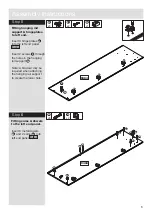

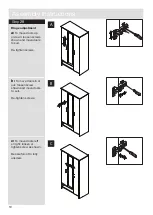

Assembly Instructions

11

x2

A:

Insert small cams

into left

and right

drawer sides.

Note:

Ensure cam arrow

points towards the edge

with hole.

Left hand side

Right hand side

622xx4504

623xx4504

622xx4504

623xx4504

A

C

C

C

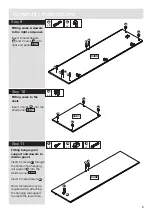

Step

16

B:

Insert wooden dowels

in drawer back

into holes in

left

right hand

drawer sides.

623xx4504

624xx7010

622xx4504

B

x2

B

Left hand side

622xx4504

Drawer Back

624xx7010

Right hand side

623xx4504

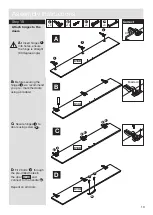

C

C:

Insert 2 metal dowels

into the the drawer

fronts .

8552

B

B

B

8552

(7010 if white)

(7010 if white)

(7010 if white)

(7010 if white)