MECHANICAL ADJUSTMENT

MOTOR BELT TENSION

CHECK:

1.

TOO TIGHT OR TOO LOOSE MOTOR BELT TENSION MAY CREATE BELT NOISE AND ALSO

TOO TIGHT MOTOR BELT TENSION CAN CAUSE THE MACHINE TO RUN SLOW AND WILL

OVERLOAD THE MOTOR.

TOO LOOSE MOTOR BELT TENSION MAY CAUSE JUMPING OF THE BELT TEETH ON THE

MOTOR PULLEY.

2.

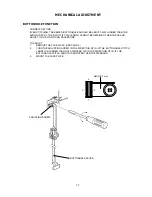

THE CORRECT MOTOR BELT TENSION IS THAT THE DEFLECTION OF MOTOR BELT IS

ABOUT 7 MM (0.28”) - 9 MM (0.36”) WHEN PUSHING THE MOTOR BELT BY FINGER AT

ABOUT 300 G LOAD.

TO ADJUST

1.

REMOVE THE BELT COVER.

2.

LOOSEN THE SCREWS (A) AND (B).

3.

MOVE THE MOTOR UP OR DOWN TO ADJUST THE DEFELECTION ABOUT 7 MM (0.28”) -

9 MM (0.36”).

4.

TIGHTEN THE SCREWS (A) AND (B).

300 g LOAD

DEFLECTION 7 - 9 mm

A

B

24