07610-004-33-05-E

19

INSTALLATION

INSTRUCTIONS

Before installing the machine, check packaging and machine for damage. Damaged

packaging is an indication there is possible damage to the product. If there is any type

of damage to both the packaging and the machine, DO NOT THROW AWAY THE

PACKAGING. The machine has been previously inspected at the factory and is expected

to arrive in new, undamaged condition. However, rough handling by carriers or others might

result in damage to the machine while in transit. If this occurs, DO NOT RETURN THE

MACHINE TO THE MANUFACTURER. Instead, contact the carrier and ask them to send

a representative to the site to inspect the damage and request that an inspection report

be completed. Contact the carrier and dealer that sold you the unit within 48 hours of

receiving the machine and report possible freight damage.

The machine should be unpacked and removed from the pallet before installing. Remove

the wooden lift beams and their associated brackets after the unit has been positioned.

Open the front door and remove all materials from inside. Once unpacked, verify there are

no missing parts. If a part is missing, contact the manufacturer immediately.

The machine is designed to operate while level. This is important to prevent any damage

to the machine during operation and to ensure the best results. The machine comes

equipped with adjustable bullet feet, which can be turned using a pair of pliers. Verify

the machine is level from front-to-back and side-to-side before making any electrical or

plumbing connections.

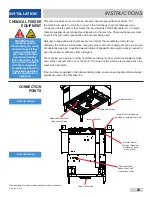

A level machine is important for proper door function as well. If the machine is level and

doors are still not functioning properly:

1. Identify the top door hinges, located in the top-front of the machine.

2. Loosen the three nuts on each hinge, which allow the doors to be adjusted.

3.

Adjust the doors to their proper position.

4.

Tighten-down the three nuts on each hinge.

All plumbing connections must adhere to local, state, territorial, and national codes. The

installing plumber is responsible for ensuring the incoming water lines are flushed of debris

before connecting the machine. Note that chips and materials from cutting processes can

become lodged in the solenoid valves and prevent them from opening or closing. Any

valves that are found to be fouled or defective because of foreign matter left in the water

line and any subsequent water damage are not the responsibility of the manufacturer.

INSPECTION

LEVELING

UNPACKING

PLUMBING

Do not throw away

the packaging if

damage is evident!

The plumber MUST flush

the incoming water line!

ADJUSTING

DOORS