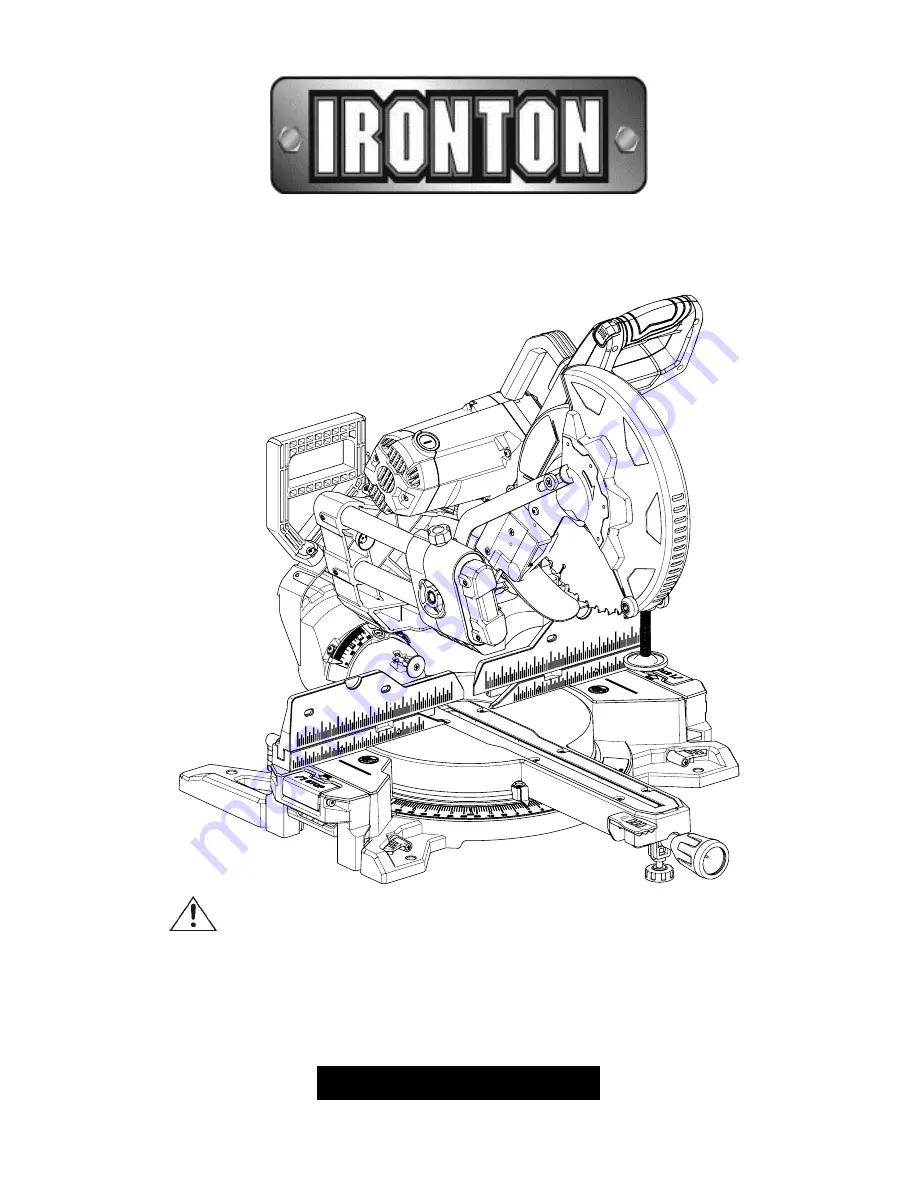

10” Multi-Slide Miter Saw

OWNER’S MANUAL

WARNING:

Read carefully and understand all

ASSEMBLY AND OPERATION INSTRUCTIONS

before operating. Failure to follow the safety rules and other basic safety

precautions may result in serious personal injury.

Item# 46780