Optidrive ODE-2 User Guide Revision 3.20

28

www.invertekdrives.com

10

Tr

o

u

b

le

Sh

oo

ti

n

g

10.

Trouble Shooting

10.1.

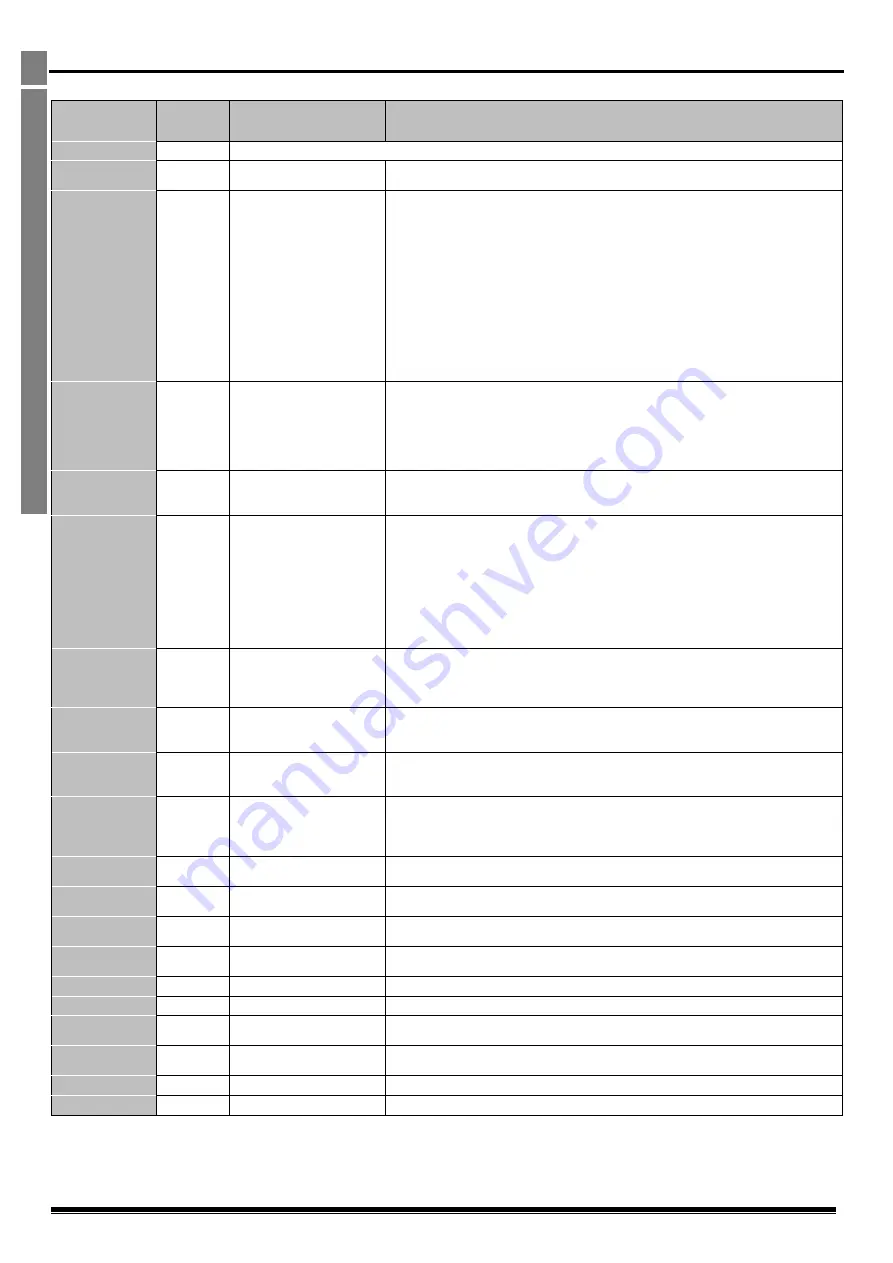

Fault Code Messages

Display

Fault Code

Fault

Number

Description

Corrective Action

0x00

Drive is healthy and in a stopped condition. The motor is not energised. No enable signal is present to start the drive

0X0A

Factory Default parameters

have been loaded

Press the STOP key, drive is ready to configure for particular application

0x03

Instantaneous Over current

on the drive output.

Excess load or shock load on

the motor.

Fault occurs immediately on drive enable or run command

Check the output wiring connections to the motor and the motor for short circuits phase

to phase and phase to earth.

Fault occurs during motor starting

Check the motor is free to rotate and there are no mechanical blockages. If the motor has

a brake fitted, check the brake is releasing correctly. Check for the correct star-delta

motor wiring. Ensure the motor nameplate current is correctly entered in P-08. Increase

the acceleration time in P-03. Reduce the motor boost voltage setting in P-11

Fault occurs when motor operating at constant speed

Investigate overload or malfunction.

Fault occurs during motor acceleration or deceleration

The Accel/Decel times are too short requiring too much power. If P-03 or P-04 cannot be

increased, a bigger drive may be required

.

0x04

Motor thermal overload

protection trip. The drive

has tripped after delivering

>100% of value in P-08 for a

period of time to prevent

damage to the motor.

Ensure the correct motor nameplate current value is entered in P-08. Check for correct

Star or Delta wiring configuration. Check to see when the decimal points are flashing

(which indicates the output current > P-08 value) and either increase acceleration ramp

(P-03) or decrease motor load. Check the total motor cable length is within the drive

specification. Check the load mechanically to ensure it is free, and that no jams, blockages

or other mechanical faults exist

0x01

Brake channel over current

(excessive current in the

brake resistor)

Check the cabling to the brake resistor and the brake resistor for short circuits or damage.

Ensure the resistance of the brake resistor is equal to or greater than the minimum value

for the relevant drive shown in the table in section 9.2

0x02

Brake resistor thermal

overload. The drive has

tripped to prevent damage

to the brake resistor

Only occurs if P-34 = 1. The internal software protection for the brake resistor has

activated to prevent damage to the brake resistor.

If an Invertek standard braking resistor is being used, P-34 MUST be 1

Increase the deceleration time (P-04) or 2

nd

deceleration time (P-24). Reduce the load

inertia

For Other Brake Resistors

Ensure the resistance of the brake resistor is equal to or greater than the minimum value

for the relevant drive shown in the table in section 9.2. Use an external thermal

protection device for the brake resistor. In this case, P-34 may be set to 2

0x05

Hardware Over Current

Check the wiring to motor and the motor for phase to phase and phase to earth short

circuits. Disconnect the motor and motor cable and retest. If the drive trips with no motor

connected, it must be replaced and the system fully checked and retested before a

replacement unit is installed.

.

0x06

Over voltage on DC bus

Check the supply voltage is within the allowed tolerance for the drive. If the fault occurs

on deceleration or stopping, increase the deceleration time in P-04 or install a suitable

brake resistor and activate the dynamic braking function with P-34

.

0x07

Under voltage on DC bus

The incoming supply voltage is too low. This trip occurs routinely when power is removed

from the drive. If it occurs during running, check the incoming power supply voltage and

all components in the power feed line to the drive.

0x08

Heatsink over temperature

The drive is too hot. Check the ambient temperature around the drive is within the drive

specification. Ensure sufficient cooling air is free to circulate around the drive.

Increase the panel ventilation if required. Ensure sufficient cooling air can enter the drive,

and that the bottom entry and top exit vents are not blocked or obstructed.

0x09

Under temperature

Trip occurs when ambient temperature is less than -10°C. Temperature must be raised

over -10°C in order to start the drive.

0x10

Faulty thermistor on

heatsink.

Refer to your IDL Authorised Distributor.

0x0B

External trip

(on digital Input 3)

E-trip requested on digital input 3. Normally closed contact has opened for some reason.

If motor thermistor is connected check if the motor is too hot.

0x0C

Comms loss trip

Check communication link between drive and external devices. Make sure each drive in

the network has its unique address.

0x0E

Input phase loss trip

Drive intended for use with a 3 phase supply has lost one input phase.

0x0F

Spin start failed

Spin start function failed to detect the motor speed.

0x11

Internal memory fault.

Parameters not saved, defaults reloaded.

Try again. If problem recurs, refer to your IDL Authorised Distributor.

0x12

Analog input current out of

range

Check input current in range defined by P-16.

-

Internal drive Fault

Refer to your IDL Authorised Distributor.

-

Internal drive Fault

Refer to your IDL Authorised Distributor.

82-E2MAN-IN_V3.20