Intel

®

Server System R2000WT Product Family System Integration and Service Guide

62

•

From the backplane accessory kit, locate the I2C cable

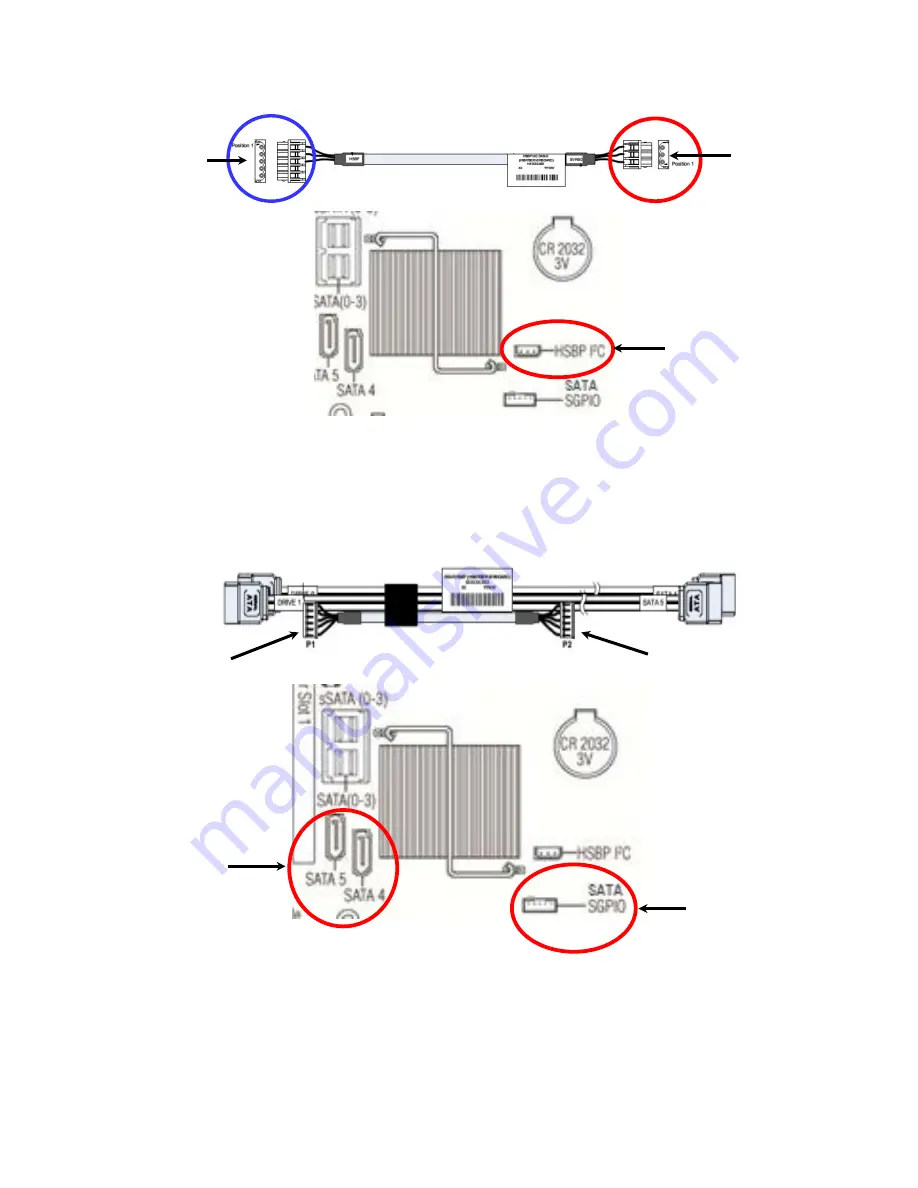

Figure 80. Rear HSBP I2C Cable – iPN H41333

•

Connect the 5-pin I2C cable connector to the matching “HSBP_ I2C” connector on the backplane

•

Connect the 3-pin I2C cable connector to the matching “HSBP_I2C” connector on the server board

•

From the backplane accessory kit, locate the Rear HSBP SGPIO & SATA Cable Bundle

Figure 81. Rear HSBP SATA & SGPIO Cable Bundle – iPN H41068

•

Match and connect the7-pin SATA “Drive 0” and “Drive 1” cable connectors to the “Drive_0” and

“Drive_1” connectors on the backplane

•

Connect the 5-pin SATA SGPIO cable connector to the “SGPIO” connector on the backplane

•

Match and connect the7-pin “SATA 4” and “SATA 5” cable connectors to the “SATA_4” and “SATA_5”

connectors on the server board

•

Connect the 5-pin SATA SGPIO cable connector to the “SGPIO” connector on the server board

3-pin HSBP I2C to

Rear Backplane

3-pin I2C to

Server Board

5-pin I2C to

Rear Backplane

5-pin SATA SGPIO to

rear Backplane

7-pin SATA ports to

rear backplane

7-pin SATA to

Server Board

5-pin SATA SGPIO to

Server Board

7-pin SATA to

rear backplane

5-pin SATA SGPIO

to rear backplane