- 7 -

1 Servo System Selection

1

Chapter 1 Servo System Selection

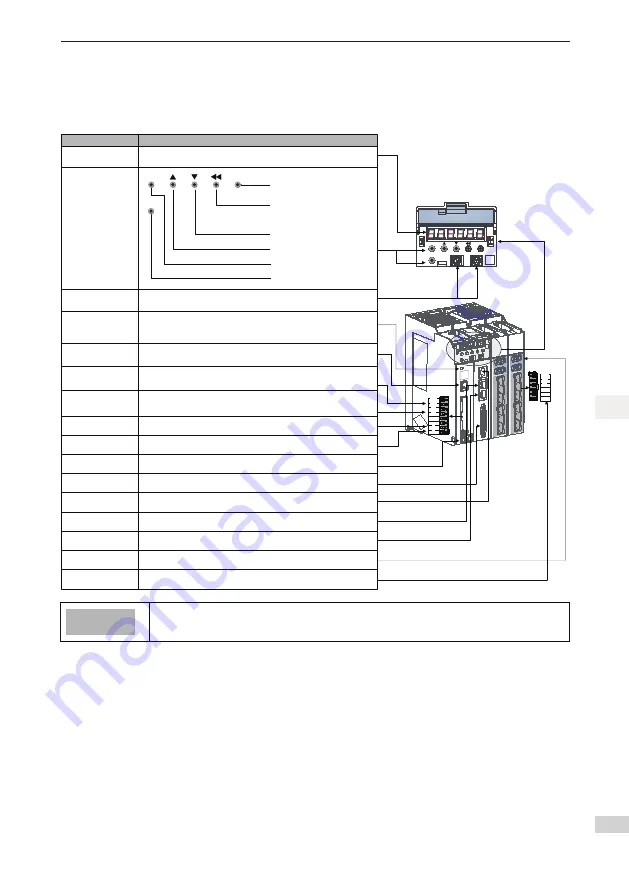

Figure 1-1 Components of servo drive

MODE

SET

SEL

IDH

IDL

Name

Purpose

Key operator

Select the specific Axis

number with the key

LED display

The 6-digital 7-segment LED display is used to show servo system

’

s running state and

parameter setting

MODE

SET

SEL

Go to the lower-level menu

Execute commands such as

storing parameter setting value

Change the value of the blinking

digit for the LED

View the high digits of the number

consisting of more than 5 digits

Decrease the value of the blinking

digit for the LED

Increase the value of the blinking

digit for the LED

Switch between all modes

Return to the upper-level menu

IDH, IDL

Setting the node address for

the equipment

BR+

BR-

PE

W

V

U

Reserved

CHARGE light

Bus voltage indicator

Used to indicate the bus capacitor with charges. When the indicator turns on,

charges possibly still exist in the internal capacitor of the servo unit, even if the power

supply of the main circuit is OFF. Therefore, do not touch the power terminals to

avoid electrical shock.

L1C

L2C

L1

P

L3

L2

C

N

L1, L2, L3

Main circuit power input

terminals

L1C, L2C

Control circuit power input

terminals

P, N

DC bus terminals

PE

Grounding terminal

CN7

24 V brake power input

CN1

Control terminal

CN3

Ethernet connection terminal

CN4

EtherCAT output terminal

CN5

EtherCAT input terminal

ErherCAT network interface, CN5 (IN) connecting to master station or previous slave station

X1, X2

Terminals used to

connect the encoder

X3, X4

Main circuit signal terminals

for the drive unit

Main circuit single-phase and three-phase 220 V power input.

Terminals L1 and L2 are for single-phase power input, and terminals L1, L2 and L3 are for

three-phase power input.

Control circuit 220 V AC power input.

P, N

:

They are used for common DC bus connection when multiple servo drives are under

parallel control.

Two grounding terminals of the servo drive are respectively connected to those of the power

supply and the servo motor.

Port for digital input/output signal

ErherCAT network interface, CN4 (OUT) connecting to next slave station

Ethernet connector port

P, C

External bleeder resistor

connection terminals

External bleeder resistor is connectedbetween P and C when the servo systemis under

feedbackBraking mode. Externalis under feedbackresistor needs to be purchased additionally.

Connect with the motor encoder terminals

BR+, BR-: Coils of the motor with brake

U, V, W: Connect the phases U, V and W of servo motor

24 V brake power input (you must use this port to input 24 V

power in order to use the brake power)

Note

The motor with brake must be supplied with 24 V power via the CN7 terminal on the servo

drive. The power must be output to the wiring terminal of the brake via BR+ and BR-.

Summary of Contents for SV820N Series

Page 128: ...127 6 Trial Running 6 2 The definition part of FB 3 Five function blocks in FB...

Page 143: ...142 6 Trial Running 6 3 Open Visual studio and create a New Twincat3 Project...

Page 146: ...145 6 Trial Running 6 Click OK Click OK...

Page 147: ...146 6 Trial Running 6 Click Yes Click OK...

Page 149: ...148 6 Trial Running 6 C The default RPDO list is as follows...

Page 150: ...149 6 Trial Running 6...

Page 152: ...151 6 Trial Running 6 7 Activate the configuration and switch over to the running mode Click...

Page 158: ...157 6 Trial Running 6 Create a new POU...

Page 159: ...158 6 Trial Running 6 Create a new FB add MC_power MC_jog MC_home MC_absolute MC_reset to FB...

Page 160: ...159 6 Trial Running 6 Call axis_motion in main Call the program in PLCTASK...

Page 181: ...Revision History Date Revised Version Revised Details May 2017 A00 First release...