Page 5

EN

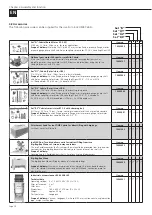

Chapter Inhalt

10 Cleaning & decommissioning ............................................................................................................... 45

10.1 Cleaning process ............................................................................................................................................46

10.2 After cleaning ................................................................................................................................................47

10.3 Decommissioning ...........................................................................................................................................48

11 Maintenance ........................................................................................................................................... 49

11.1 Maintenance plan ..........................................................................................................................................49

11.2 Dirt trap sieve in the water inlet ..................................................................................................................49

11.3 Dirt trap sieve in the pressure reducing valve .............................................................................................49

11.4 Set values .......................................................................................................................................................49

11.5 Wear limits .....................................................................................................................................................50

11.5.1 Metering shaft wear limit ..........................................................................................................................50

11.5.2 Mixing shaft wear limit ..............................................................................................................................50

11.5.3 Pump shaft wear limit ................................................................................................................................50

12 Dismantling and disposal ..................................................................................................................... 55

12.1 Safety ..............................................................................................................................................................55

12.2 Dismantling ....................................................................................................................................................55

12.3 Disposal ..........................................................................................................................................................55

13 Systems ................................................................................................................................................... 56

13.1 EC declaration of conformity ........................................................................................................................56

13.2 General Terms of Business of the company INOTEC GmbH ........................................................................57

13.3 Feeding and earthing ....................................................................................................................................58

13.3.1 Circuit diagram: Load circuits 01 ................................................................................................................................59

13.3.2 Circuit diagram: Load circuits 02 ................................................................................................................................60

13.3.3 Circuit diagram: Direction of rotation changeover ......................................................................................................61

13.3.4 Circuit diagram: Contactor control .............................................................................................................................62

13.3.5 Circuit diagram: Sensors .............................................................................................................................................63

13.3.6 Circuit diagram: Operating switch ..............................................................................................................................64

13.3.7 Circuit diagram: Pump ...............................................................................................................................................65

13.3.8 Circuit diagram: Nano 01 ...........................................................................................................................................66

13.3.9 Circuit diagram: Nano 02 ...........................................................................................................................................67

13.3.10 Circuit diagram: Nano 03 .........................................................................................................................................68

13.3.11 Circuit diagram: Nano 04 .........................................................................................................................................69

14 Order form .............................................................................................................................................. 70

15 Index ....................................................................................................................................................... 71

16 Locations ................................................................................................................................................ 72