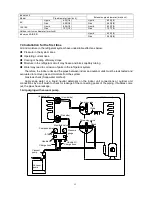

6. Indoor units combination

6.1 Indoor unit combination for VOM20H2RE102

Comb.

Suggested Combination

Limit

Dual(1x1)

9

None

12

Dual (1x2)

9+9

9+12

—

6.2 Indoor unit combination for VOM30H2RE103

Comb.

Suggested Combination

Limit

TRI (1x1)

9

The 18k indoor unit should

not be Floor Ceiling or Duct

unit;

There should be only one

Floor Ceiling or Duct unit;

12

18

TRI (1x2)

9+9

9+12

9+18

12+12

12+18

TRI (1x3)

9+9+9

9+9+12

9+9+18

9+12+12

6.3 Indoor unit combination for VOM42H2RE104

Comb.

Suggested

C

bi

ti

Limit

QUA

(1x1)

9

None

12

18

QUA

(1x2)

9+9

9+12

9+18

12+12

12+18

18+18

QUA

(1x3)

9+9+9

9+9+12

9+9+18

9+12+12

9+12+18

9+18+18

12+12+12

12+12+18

12+18+18

QUA(1x

4)

9+9+9+9

9+9+9+12

9+9+9+18

9+9+12+12

9+9+12+18

9+12+12+12

9+12+12+18

12+12+12+12

9