17

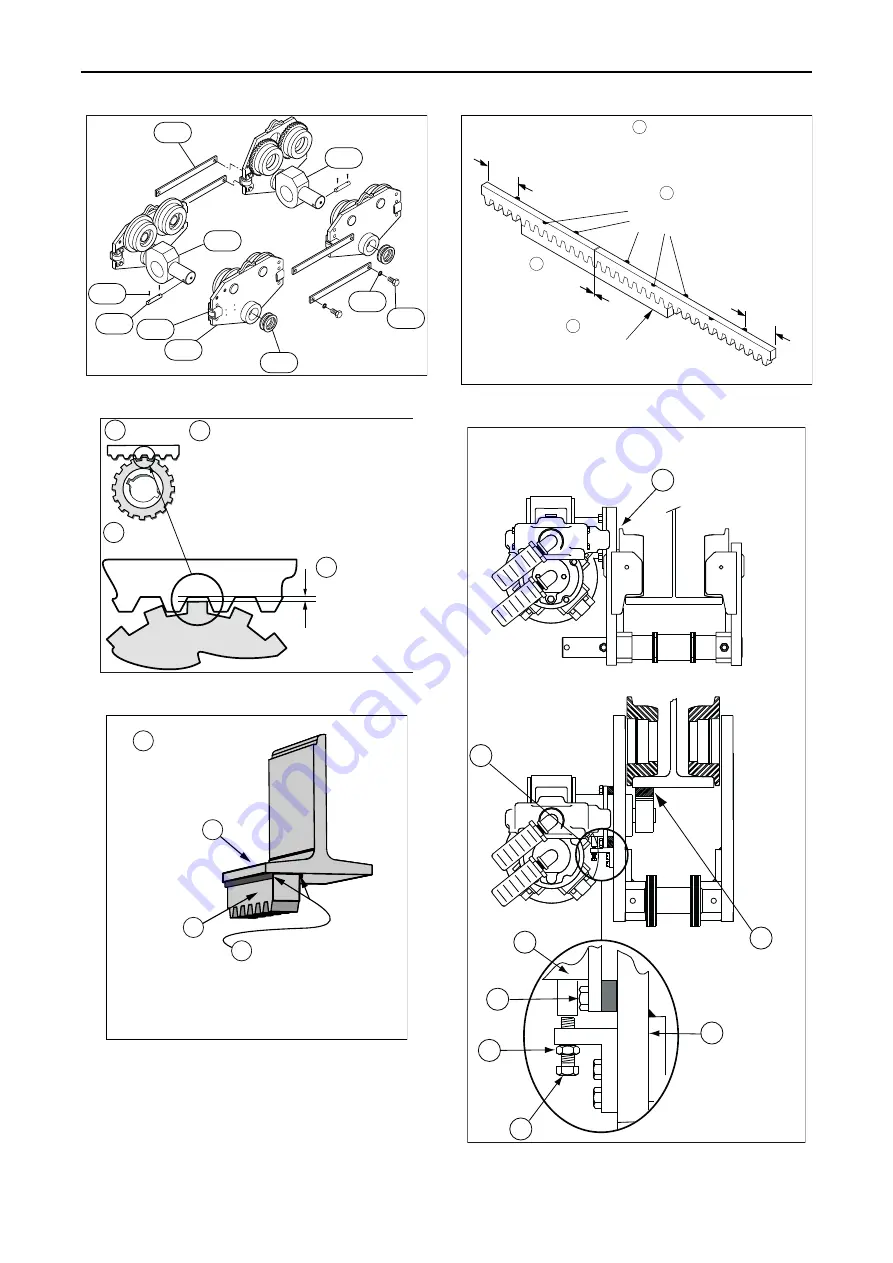

Figure 5. MHP0352

159

170

158

156

150

165

173

174

157

170

Figure 6. MHP1177

Maintain clearance between rack and

pinion teeth of 0.06 inch (minimum) to

0.10 inch (maximum) [1.5 to 2.5 mm] to

prevent pinion binding during operation.

Measure gap between outside

diameter of drive pinion and root of

rack segment.

Note: 0.08 inch feeler gauge use is

recommended.

Rack

Pinion

0.06 to 0.10 inch

(1.5 to 2.5 mm)

A

B

C

D

Figure 7. MHP1178

Rack

Segment

Lower Beam

Flange

A

Hoist Trolley

Drive Assembly

Mounted This Side.

Fillet Weld:

• Allow 1/4 inch (6.5 mm)

clearance between edge

of lower flange and rack

segment.

• Apply weld to both sides

of rack segment.

B

C

D

Figure 8. MHP3016

B

C

D

6 inches

(152 mm)

6 inches

(152 mm)

Stagger welds

along rack

A

(Not to scale)

Use rack guide for

correct track positioning

Check clearance

between racks

0.08” (2 mm)

Figure 9. MHP1605

A

Normal trolley drive mounded

above supported bean between

trolley wheels

Located behind

motor housing

Reducer

Adapter

Mounting

Capscrew

Jam Nut

Side Plate

Adjustment

Capscrew

Trolley rack drive

mounted below

support beam

B

G

H

D

C

E

F