88-A952V001-1B-EN

35

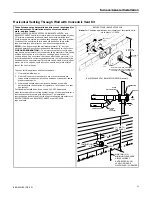

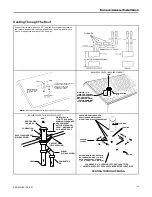

Horizontal Venting Through Wall with Concentric Vent Kit

These Furnaces may be installed as direct vent (as shipped) or

as nondirect vent. Installation must conform to national,

state, and local codes.

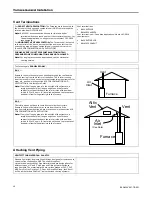

The BAYVENT200B, BAYVENTCN200B, BAYAIR30AVENTA, and

BAYAIR30CNVENT vent & inlet terminals kits must be located at least

12" minimum above normally expected snow accumulation level.

Avoid areas where staining or condensate drippage may be a problem.

Location of the vent/wind terminal should be chosen to meet the

requirements for either direct or non-direct vent applications.

PITCH —

Venting through the wall must maintain 1/4" per foot

pitched upward to insure that condensate drains back to the Furnace.

FLUE GAS DEGRADATION —

The moisture content of the flue gas

may have a detrimental effect on some building materials. This can be

avoided by using the roof or chimney venting option. When wall

venting is used on any surface that can be affected by moisture, it is

recommended that a corrosion resistant shield (24 inches square) be

used behind the vent terminal. This shield can be wood, plastic, sheet

metal, etc. Also, silicone caulk all cracks, seams and joints within 3

feet of the vent terminal.

The vent for this appliance shall not terminate

1.

Over public walkways; or

2.

Near soffit vents or crawl space vents or other areas where

condensate or vapor could create a nuisance or hazard or cause

property damage; or

3.

Where condensate vapor could cause damage or could be

detrimental to the operation of regulators, relief valves. or other

equipment.

For Canadian installations, if you used a ULC-S636 approved

manufactured modular venting system, a copy of the manufacturer's

instructions should remain with the system. The installation

instruction can be obtained from the vent termination manufacturer.

BAYVENTCN200B and BAYAIR30CNVENT meet ULC-S636

requirements.

BAYVENT200B / BAYVENTCN200B

Note:

For Canadian applications, horizontal vent termination kits

must meet ULC-S636.

VENT

COMBUSTION

AIR

VENT

VENT

PLATE

VENT

CAP

12" MINIMUM

TO OVERHANG

MAINTAIN 12" MINIMUM CLEARANCE

ABOVE HIGHEST ANTICIPATED SNOW LEVEL

OR GRADE WHICHEVER IS GREATER

SCREWS

(4 req.)

ANCHORS

(4 req.)

7.2"

3.2"

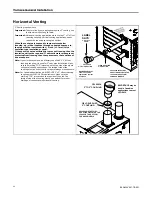

BAYAIR30AVENTA / BAYAIR30CNVENT(Sidewall)

RAIN CAP

COMBUSTION AIR

STRAP

(FIELD SUPPLIED)

COMBUSTION

AIR

VENT

ELBOW

(FIELD

SUPPLIED)

VENT

1" + 1/2"

COMBUSTION

AIR

12" MIN TO

OVERHANG

1" + "

VENT

1

2

MAINTAIN 12 IN.

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SHOW

LEVEL OR GRADE

WHICH EVER IS GREATER