TITAN GO Product Manual |

Wiring and Connections

INGENIA | 2022-07-14 08:35:14

68

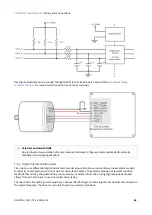

7.5.4 Analog encoder (Sin-Cos encoder) interface

The Titan Go can use analog encoder (also known as Sin-Cos encoder) as position and velocity feedback element.

This sensor provide a pair of quadrature sine and cosine signals as the motor moves, which frequency depends on

the motor speed. The signals may be generated by optical or magnetic means. For noise immunity the signals are

typically transmitted differentially from the encoder to the sensor interface electronics.

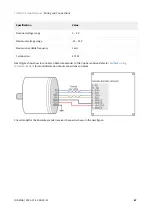

Pin

Signal description

Signal example

SIN+

Sine wave with 2.5 V offset and 0.5 Vpp

SIN-

Same as SIN+, but with 180º phase shift

COS+

Cosine with 2.5 V offset and 0.5 Vpp

COS-

Same as COS+, but with 180º phase shift

Summary of Contents for Titan GO

Page 19: ...TITAN GO Product Manual Product Description INGENIA 2022 07 14 08 35 14 19 ...

Page 56: ...TITAN GO Product Manual Wiring and Connections INGENIA 2022 07 14 08 35 14 56 ...

Page 89: ...TITAN GO Product Manual Wiring and Connections INGENIA 2022 07 14 08 35 14 89 ...

Page 101: ...TITAN GO Product Manual Wiring and Connections INGENIA 2022 07 14 08 35 14 101 ...