11

7

INS

TALLER

US

ER

MAINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

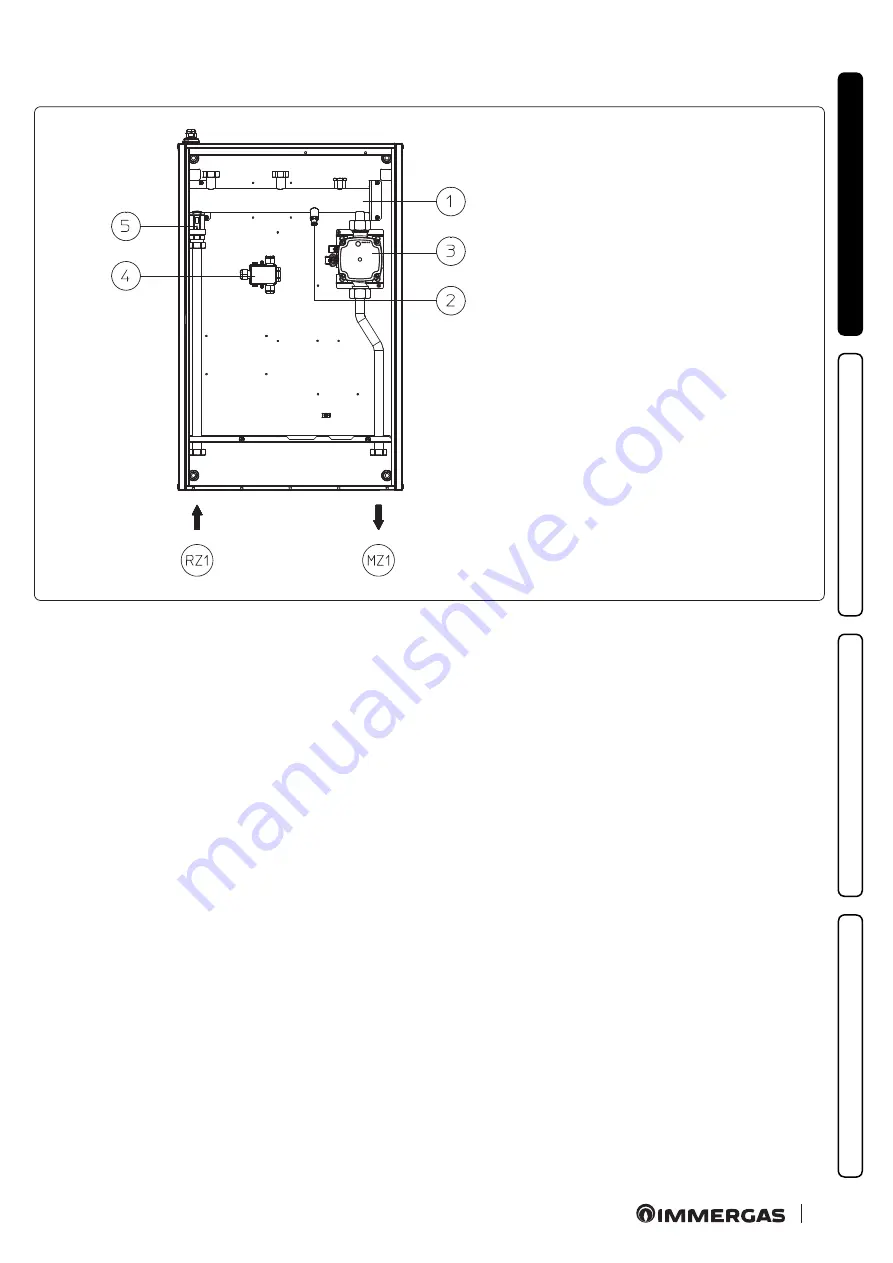

1.8 MAIN COMPONENTS.

Key:

1 - Hydraulic manifold

2 - Drain fitting

3 - Pump

4 - Electrical connection box

5 - “Europa” one-way valve

MZ1 - Direct zone 1 flow

RZ1 - Direct zone 1 return

1.9 SIZING THE SYSTEMS.

The flow temperatures to the various system zones may be reduced

compared to the boiler outlet temperatures, according to the

mixture of the flow and return fluids inside the DIM. In the event

that the DIM is used to feed Low Temperature zones, check that

the design parameters allow you to achieve a maximum surface

temperature of the radiant floor in compliance with standard

UNI EN 1264.

1.10

COMMISSIONING THE DEVICE.

System filling.

Once the device is connected, fill the system via

the boiler filling valve.

Filling is performed at low speed to ensure release of air bubbles

in the water via the boiler and central heating system vents and

of the distribution manifold (if any).

Close radiator vent valves when only water escapes from them.

Close the filling cock when the boiler pressure gauge indicates

approx. 1.2 bar.

N.B.:

during these operations, start the circulation pump by ac-

tuating the main switch on the boiler control panel after having

activated the RT.

1.11

KITS AVAILABLE ON REQUEST.

• System cut-off cock kit (on request). The manifold is designed

for installation of system interception cocks to be placed on

flow and return pipes of the connection assembly. This kit is

particularly useful for maintenance as it allows the DIM to be

drained separately without having to empty the entire system.

The above-mentioned kits are supplied complete with instructions

for assembly and use.