en

17

User manual Monika 2, Rota

www.igloo.pl

It is essential to keep the

condenser of the device

cle-

an. Dirt may hinder the heat exchange, causing mainly

increase in electric energy consumption and may cause

damage of aggregate compressor.

In order to clean the condenser it is necessary to

unscrew the sheet metal screws and pull the wind brace

out. Clean condenser lamellas with help of soft brush or

paint brush. If the condenser is extremely dirty (blocked

lamellas) it is indicated to use vacuum cleaner or com-

pressed nitrogen to suck / blow the dirt from between

lamellas.

The producer shall not be held responsible for damages of the condenser aggregate resulting from non-

observance of condenser cleanliness!

Door seal should be cleaned solely with clean water without any cleansing agents and it sho-

uld be thoroughly dried. The seal cannot get into contact with oily substances or grease!

Control whether door close properly during maintenance procedures.

Test: place a sheet of paper between the seal and the casing and close the door. The paper

should pose a tangible resistance during an attempt to pull it out.

During maintenance services it is necessary to pay attention not to damage the data place of the device

Fig.12 (p.18), which contains signi

fi

cant information for servicing organs and waste removal companies.

6. SERVICE

6.1. Fault identi

fi

cation and repair

In case of any dif

fi

culties during actuation of the device or during its exploitation, please return to these chapters in this ma-

nual, which explain the performed operation. This aims to ensure that the device is properly operated. If you still experience

dif

fi

culties, the following hints will help you solve the problem.

The device is not working... – Make sure that:

• The device is connected to the supply network

• Voltage and frequency in the network are compliant with those recommended by the producer, 230V/50Hz

• The main switch is turned on

• Thermostat is turned on (This concerns the Igloo thermostat – If only two spots are visible on the display – turn on

the thermostat)

The device is operating, but the lighting is off...– Make sure that:

• Lighting switch is turned on

• Fluorescent lamp or starting switch of the device are not burnt

Water leakage from below the device or into the inside of the chamber:

• Check whether the device is properly levelled

• Check the patency of out

fl

ow pipes

• Empty the condenser tray or container

• Check whether there is not too much ice in the rail and on the condenser – defrost when necessary

Fig.10 Cleaning the condenser

Elements of device can corrode when improper used and maintenance. To avoid that please

follow the rules:

• Do not allow contact of the surface of the device with substances containing chlorine and / or baking

soda in different varieties, which destroy the protective layer and components of the device (also

includes various stainless steel)

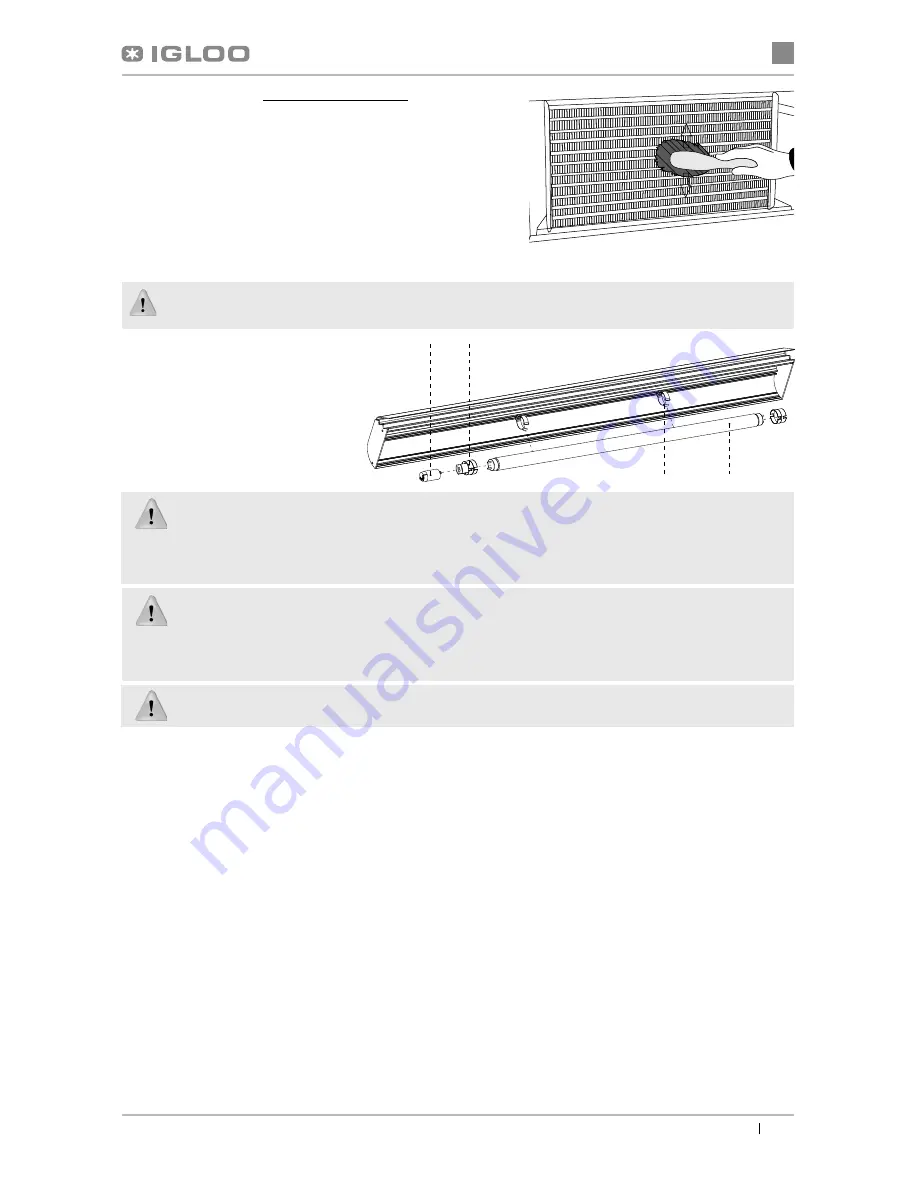

Fig.11 Changing the

fl

uorescent lamp

1 – Fluorescent lamp handle

2 – Fluorescent lamp

3 – Casing of

fl

uorescent lamp and

starting switch

4 – Starting switch of

fl

uorescent lamp

3

4

2

1