14

7.2 Version with welding end

•

Respect installation position!

•

Remove protection caps from connection flanges. Caps

only

serve as transport

protection.

•

Assembly only by using welding process 111 (manual arc welding) and 141

(tungsten inert gas welding).

7.3 Heat treatment of weld seams

Supplementary temper tests of weld seams are not required.

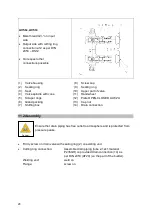

7.4 Flap indicator

•

The centre of the lower process connection is the reference point for the zero mark of

the flap indicator (3).

•

The flap indicator fixed by bolt springs (3.1) with stop clamp (3.2) to the standpipe

(factory-made) can be turned into desired position.

Also turn stop clamp!

7.5 Float installation

•

The float (2.1) with inner magnetic system and the new gasket (2.2) are packed and

fixed outside of the standpipe (2) when the unit is supplied.

•

Open cover flange (2.3)

•

Carefully remove float packing

•

Insert float with top-heavy side upwards into standpipe (top-heavy side with colour

marking)

•

Tighten cover flange (2.3) and associated gaskets (2.2) with standpipe using

successively opposite diagonal tightening (see chapter 9.2)

Remove float before carrying out pressure test of boiler!

Float may remain in standpipe if there are valve between boiler and

standpipe which are closed during the test.

7.6 Drain piping

•

Check bolting drain valve (A) / standpipe (2) and retighten if necessary.

•

Mount drain piping on drain valve (A) (to be provided by the customer).

Ensure that drain piping has free outlet to atmosphere and is protected

from pressure peaks!

•

Close valves.

Caution

Caution