mobileIoT gateway

CR3158

7

Restart the device to update to the newly configured mode.

When bit 7 is written, the device restarts.

4.3.1 Real-time mode

In real-time mode, bidirectional transmission of CAN messages occurs.

The unit can send/receive process data (e.g. machine parameters) via CAN interfaces during

operation via Bluetooth/WLAN, the mobile network and the

mobile

IoT platform. Depending on the

design, it can transmit data from the GNSS receiver and the input/output functions and forward them

via the CAN bus. Alternatively, the unit can receive the data from an external receiver (e.g.

CANwireless) via a WLAN or Bluetooth connection and send it to the

mobile

IoT platform.

The data is continuously transmitted and can be evaluated in near real-time. For this function, there

must be a permanent connection between the unit and the user software or the

mobile

IoT platform.

This mode also supports a real-time connection from Codesys 2.3. This requires appropriate software

and a

mobile

IoT data contract.

The real-time mode can be set locally via an SDO or via the

mobile

IoT suite in the machine properties.

In real-time mode, no data or messages are stored on the

mobile

IoT platform.

4.3.2 Cloud logging mode

The cloud logging mode allows GNSS position data to be sent automatically to the mobileIoT platform.

In this mode, metrics can be actively generated and sent by the application controller and also allow

the gateway to autonomously log data available on the CAN bus.

Data linking to the application controller is configured in the mobileIoT suite. There the corresponding

source code will be automatically generated, which can be loaded into the controller programme.

No data is sent to the mobileIoT platform during real-time connection. As soon as the real-time

connection is terminated, data is captured again and sent to the mobileIoT platform.

4.4 Input/output functions

The device has additional input/output functions (3 analogue inputs, 1 digital output). For example, the

input function can be used to collect device or machine status information or to directly detect and

monitor switch states. The data determined via the input/output functions can be visualised or

transferred via the CAN bus.

The input/output functions are accessed via the following objects:

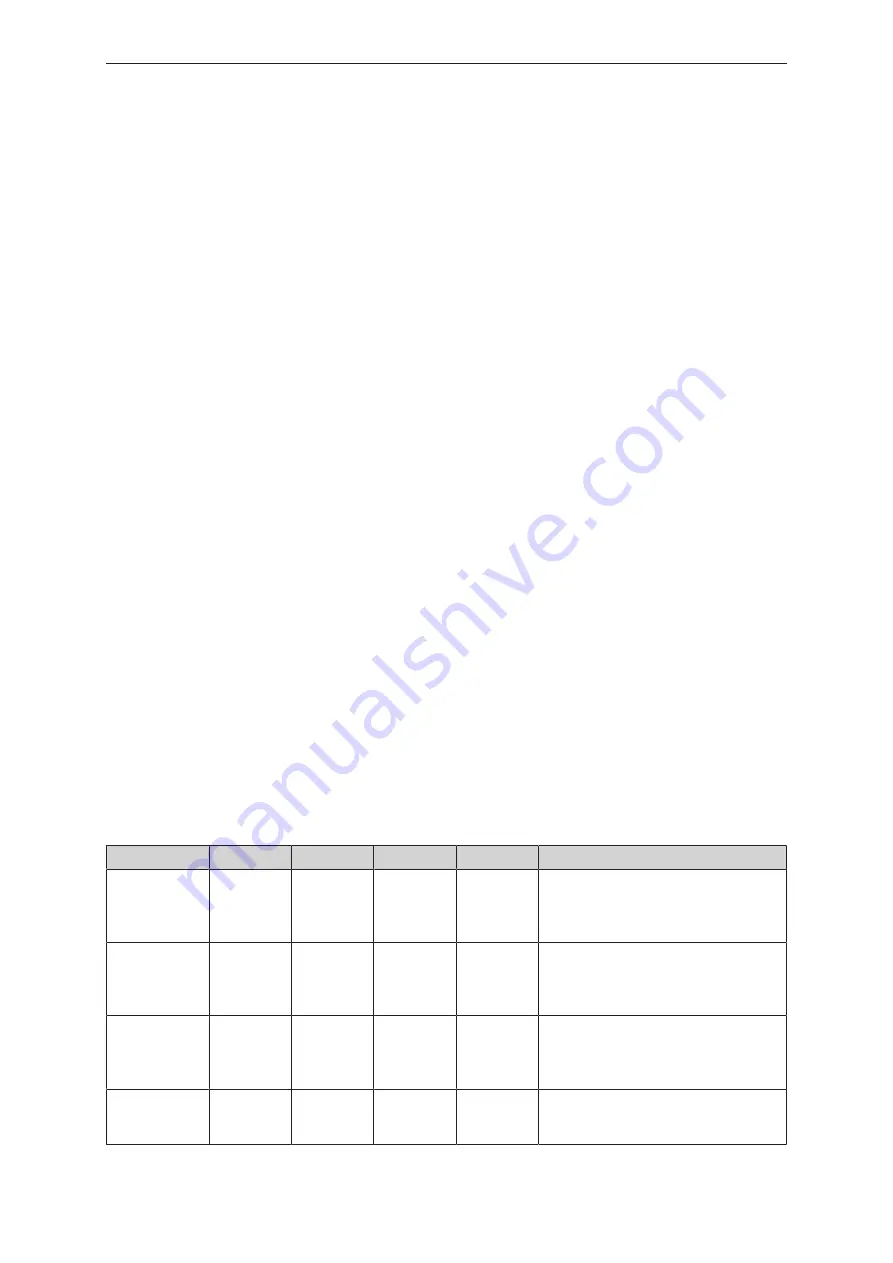

Object

Index

Subindex

Type

Default

Description

Analogue input 1

0x546F

0x14

R32

ro

—

Pin 4 of the 14-pin Micro Timer II connector

Raw value of the analogue input measure-

ment (Volt)

No filtering applied

Analogue input 2

0x546F

0x15

R32

ro

—

Pin 5 of the 14-pin Micro Timer II connector

Raw value of the analogue input measure-

ment (Volt)

No filtering applied

Analogue input 3

0x546F

0x16

R32

ro

—

Pin 6 of the 14-pin Micro Timer II connector

Raw value of the analogue input measure-

ment (Volt)

No filtering applied

IO – clamp 30

voltage

0x3333

0x67

R32

ro

—

Terminal 30

Raw value of the analogue input measure-

ment (Volt)