3: I

NSTRUCTIONS

R

EFERENCE

3-10

FC6A S

ERIES

MICROS

MART

L

ADDER

P

ROGRAMMING

M

ANUAL

FC9Y-B1726

User Program Execution Errors

When an advanced instruction is executed, a user program execution error occurs when any of the following conditions are met.

• the result of the adavnced instruction is invalid

• source or destination device that is indirectly specified in the advanced instruction exceeds the valid device range

• the advanced instruction does not operate correctly

For example, the data in the source device does not comply with the normal floating-point format when the data type is Float (F).

For details about device ranges, see "Devices" on page 2-1.

When a user program execution error occurs, special internal relay M8004 turns on and the corresponding error code is stored in

special data register D8006. For details about the error codes, see "User Program Execution Error" on page A-12.

When a user program execution error occurs, instructions operate as follows:

• When the source data is invalid, the execution of the advanced instruction is canceled and the data in the destination device is not changed.

• When the execution result is invalid, a value is stored in the destination device.

For details on stored values, see the descriptions of relevant instructions.

• If a user program execution error occurred during a repeat operation, the operation is canceled and the next repeat operation is executed.

M8004 is retained even when no further user program execution errors occur during subsequent repeat operations.

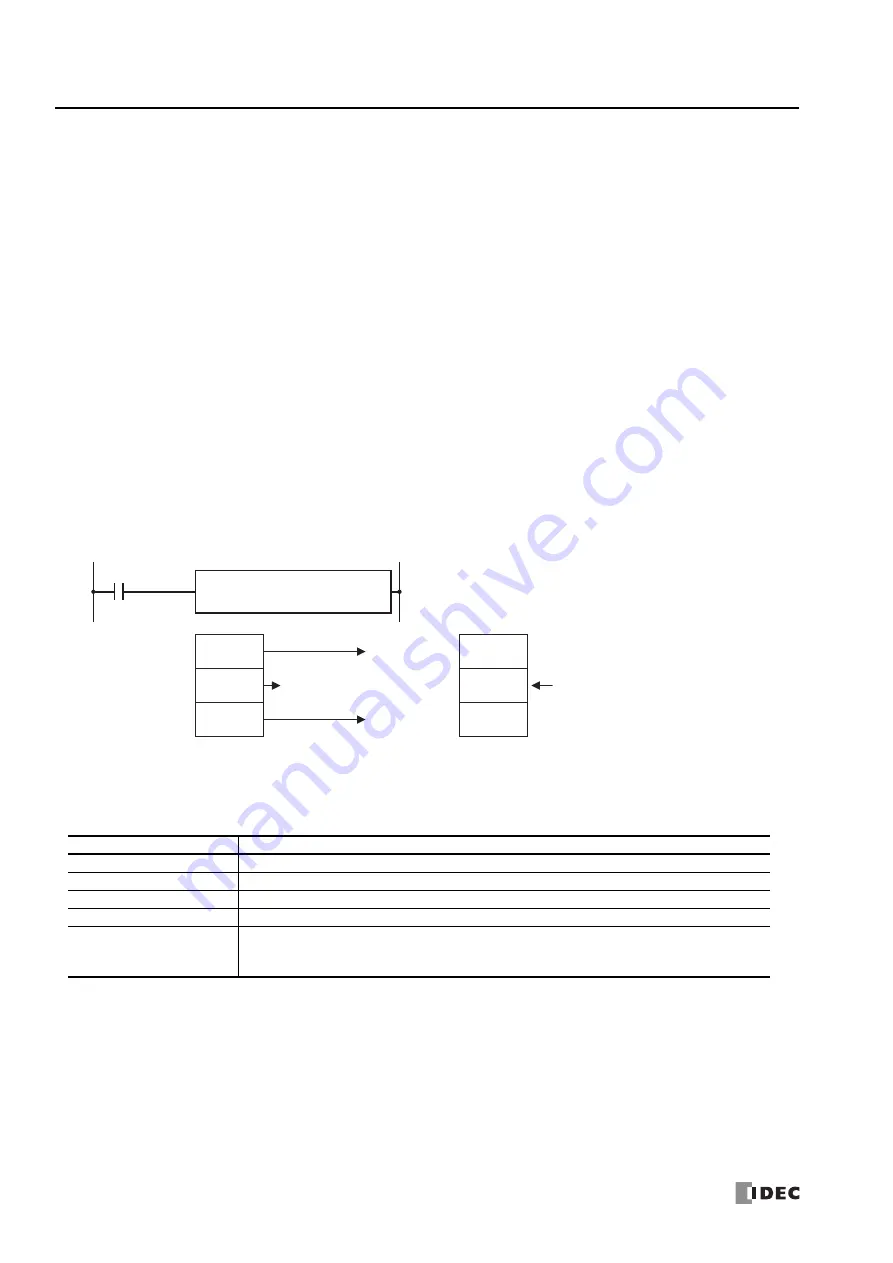

Example: User program execution error during a repeat operation

When the source data does not comply with the normal floating-point format.

When the second repeat operation is executed, special internal relay M8004 turns on because the source data is not a normal

number in floating-point format.

The second repeat operation is canceled and the third repeat operation is executed.

Carry and Borrow

When the result of an operation exceeds the valid device range, a carry (CY) or borrow (BW) occurs.

Carrying and borrowing occur in the following conditions according to the data type:

When a carry or borrow occurs, special internal relay M8003 (carry and borrow) turns on.

For example, when D0 has a value of FFFF (hex) and +1 is added using an INC instruction, the result is 10000 (hex), but when the

data type is Word (W), 0000 (hex) is stored in D0 and 1 is stored in M8003.

(D0, D1)

3.14

(D2, D3)

(D4, D5)

1.414

(D100, D101)

(D102, D103)

(D104, D105)

3.14

1.414

MOV(F)

S1(R)

D1(R)

REP

D0

D100

3

Not a normal

number

Not executed

M8004=ON

Previous value is

retained

Data Type

Status

Word

Exceeds range between 0 and 65,535

Integer

Exceeds range between -32,768 and 32,767

Double Word

Exceeds range between 0 and 4,294,967,295

Long

Exceeds range between -2,147,483,648 and 2,147,483,647

Float

If an overflow or underflow occurs

For details on overflow and underflow, see "Carry and Borrow in Floating-Point Data Processing" on

page 3-8.

Summary of Contents for MICROSmart FC6A Series

Page 1: ...B 1726 7 FC6A SERIES Ladder Programming Manual ...

Page 8: ...Preface 7 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 32: ...1 OPERATION BASICS 1 20 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 96: ...3 INSTRUCTIONS REFERENCE 3 18 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 130: ...4 BASIC INSTRUCTIONS 4 34 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 192: ...9 SHIFT ROTATE INSTRUCTIONS 9 12 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 272: ...12 DISPLAY INSTRUCTIONS 12 24 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 284: ...14 REFRESH INSTRUCTIONS 14 6 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 502: ...25 DATA LOG INSTRUCTIONS 25 22 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 546: ...26 SCRIPT 26 44 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 598: ...APPENDIX A 14 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...